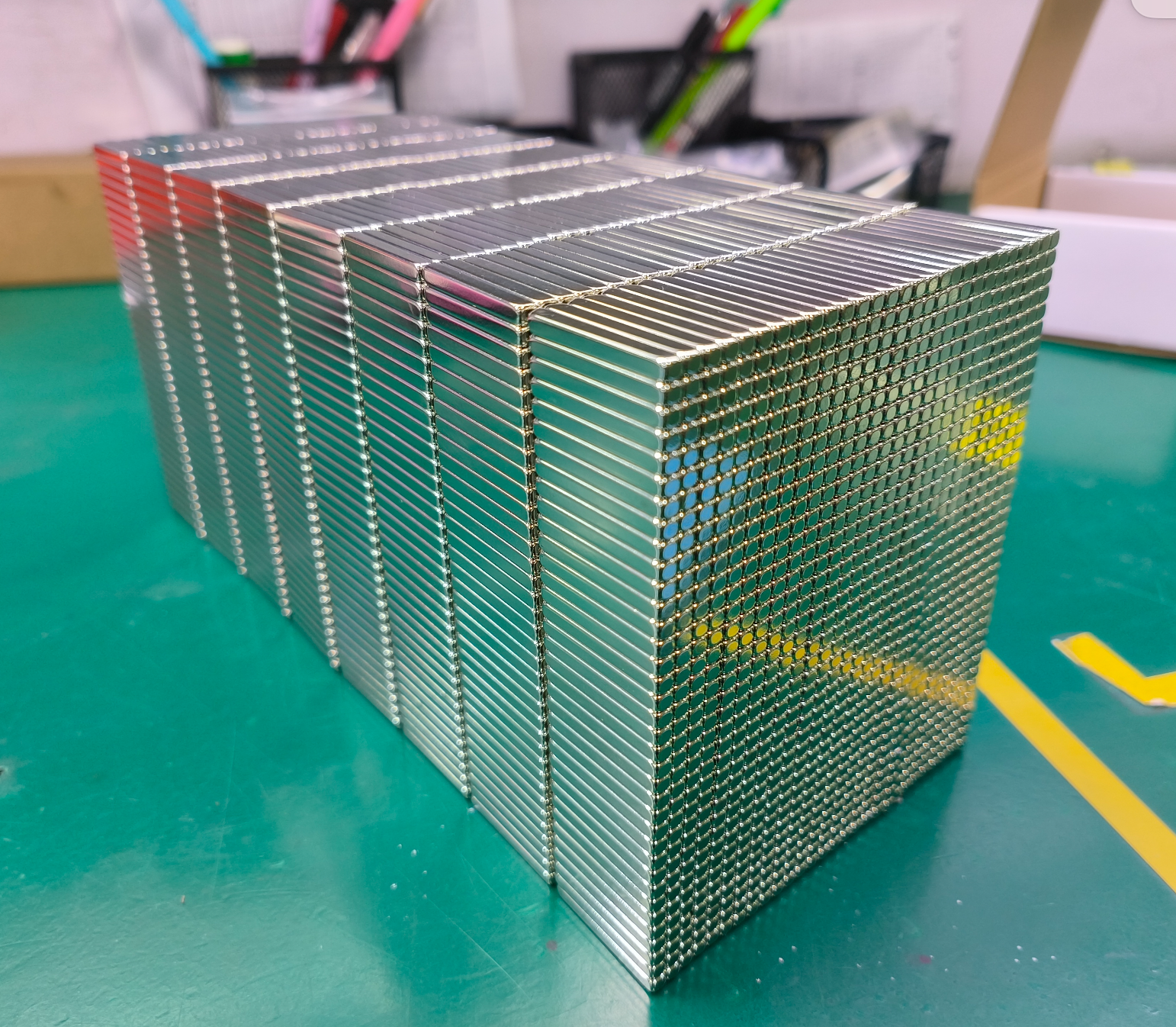

Product Name: Square High-Performance NdFeB Magnet

Material Grade: N35 (Remanence Br ≥12.3 kGs, Intrinsic Coercivity Hcj ≥10.8 kOe)

Dimensions: L10×5×3mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2500±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.0 mWb (measured with flux meter)

1. Product Overview

This product is a high-performance square-shaped NdFeB magnet with grade N35, featuring relatively high magnetic strength, strong demagnetization resistance, and precise dimensional accuracy. The product precision can be customized according to customer requirements. Its sophisticated special-shaped design meets high-performance magnetic requirements in compact spaces, making it widely applicable in various scenarios.

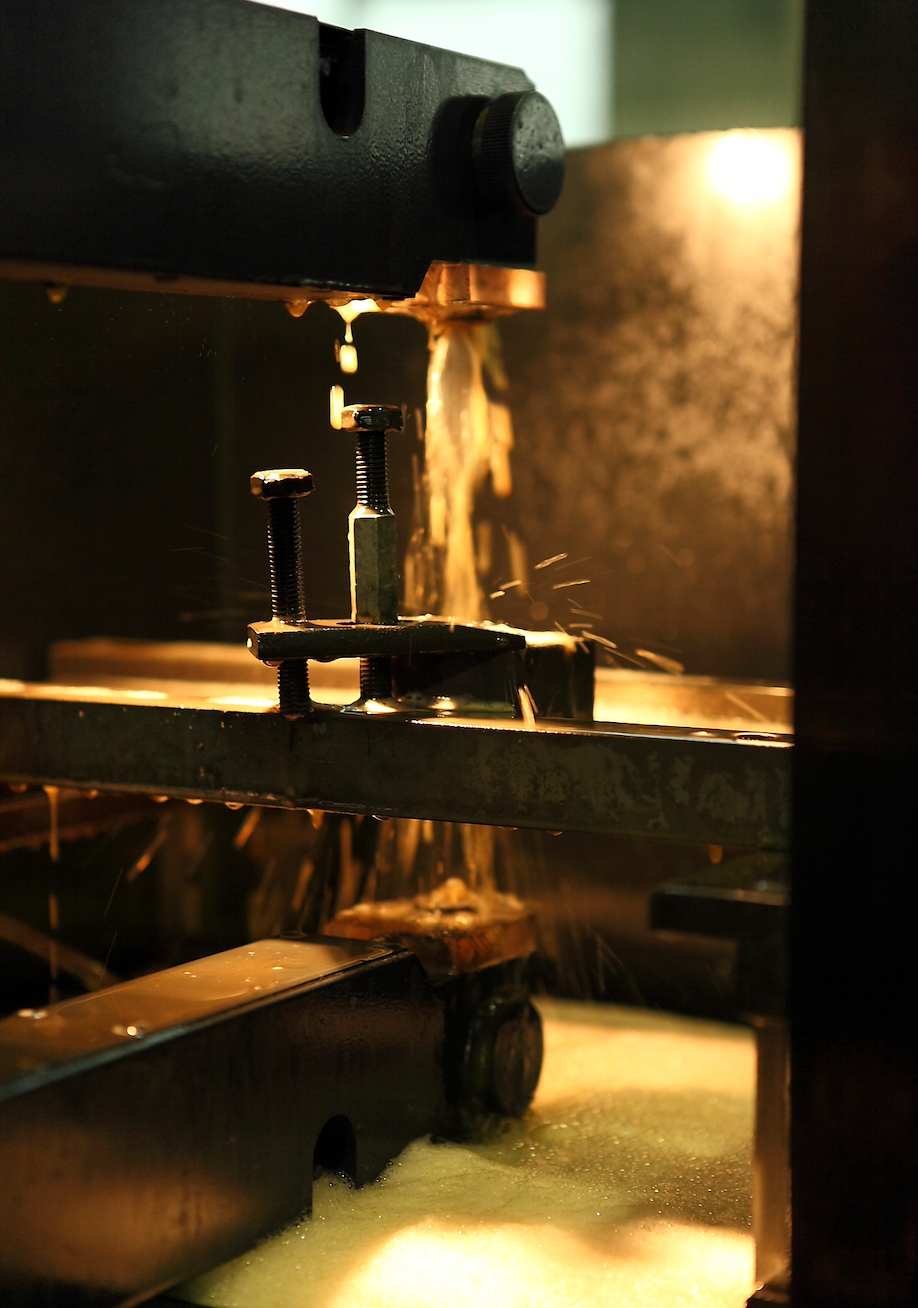

The magnet is manufactured using advanced wire cutting processes, ensuring neat edges and uniform dimensions. Its surface treatment consists of multi-layer metal coating (Ni+Cu+Ni) or optional Zn coating, effectively preventing oxidation, corrosion and other environmental impacts, thereby extending the product's service life.

2. Technical Specifications

Product Name: Square High-Performance NdFeB Magnet

Material Grade: N35 (Remanence Br ≥12.3 kGs, Intrinsic Coercivity Hcj ≥10.8 kOe)

Dimensions: L10×5×3mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2500±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.0 mWb (measured with flux meter)

3. Manufacturing Process

This product is manufactured through the following key process:

Wire Cutting: Molybdenum wire cutting of stepped profile (accuracy ±0.03mm, requires segmented programming)

4. Surface Treatment and Coating Technology

To improve the magnet's corrosion resistance and appearance quality, the following surface treatment solutions are adopted:

Default Coating: Three-layer nickel-copper-nickel (Ni-Cu-Ni), customizable according to customer requirements

Coating Thickness Standard: Ni (3μm) + Cu (5μm) + Ni (4μm), customizable according to customer needs

Optional Coating: Precious metal gold/silver coating with excellent conductivity and corrosion resistance

Coating Characteristics:

Salt spray corrosion resistance and improved oxidation resistance

Increased surface hardness to prevent scratches

Improved appearance glossiness, suitable for exposed components

5. Appearance and Dimensional Inspection Standards

To ensure consistent and reliable product quality, all products undergo the following inspection processes:

» Manual dimensional inspection with micrometers/calipers

» Visual inspection (light source illumination 800-1200 lumens, standard inspection distance 20-750px)

» 2D image measuring instrument inspection (for special-shaped and non-standard structures)

» CCD intelligent sorting machine for automatic sorting and full inspection of product appearance and dimensions

» Magnetic flux testing (to ensure batch consistency of magnetic performance)

6. Reliability Testing

6.1 Neutral Salt Spray Test (NSS):

Temperature: 35±2°C

Salt spray deposition rate: 1-2ml/2000px²·h

pH value: 6.5-7.2

Test duration: 24h/48h/72h/96h, can be set according to application scenarios/customer requirements/project requirements

6.2 Temperature Demagnetization Test:

Place in constant temperature oven (80°C) for 2 hours, test duration can be adjusted according to customer requirements

Demagnetization rate ≤10% is qualified

Simulates temperature stability in practical applications

6.3 Drop Test Note:

This product is not suitable for "tool magnet" drop tests, as NdFeB is a brittle material and strong impacts may cause edge chipping/breakage

7. Packaging Process and Instructions

We implement professional packaging methods according to magnetic product transportation requirements:

» Remove defective products in appearance and dimensions

» Uniformly magnetize qualified products and arrange them neatly

» Customized box quantities/labels according to customer requirements

» Each box uses vacuum packaging with anti-magnetic separator plates and shock-absorbing pads

» Small boxes are packed into master cartons with moisture-proof, shock-proof and anti-magnetic interference protection

Packaging methods can be customized.

8. Usage Precautions

Handle with care: NdFeB is a brittle material - avoid impacts, collisions or drops

Avoid pinching: The magnetic force is extremely strong - always slide to separate rather than pulling apart

Polarity identification: Install correctly according to stepped configuration to avoid equipment malfunction

Moisture and corrosion prevention: Store away from high temperature, high humidity, strong acid/alkali environments

Keep away from sensitive devices: Keep strong magnets away from hard disks, IC cards, pacemakers, etc.

9. Customization and Services

We support various customization services:

» Size, shape, coating (layers, thickness, color) customization

» Polarity direction and magnetic strength customization

» Laser LOGO or serial number marking

» Special application packaging solutions and pull force testing support

For samples, technical parameter tables, MSDS, RoHS, ISO9001, QC08000, IATF16949, ISO14001, ISO27001 certificates and other documents, please contact our sales engineers.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat