1. Product Overview

Sintered NdFeB (Neodymium-Iron-Boron) permanent magnets are the strongest commercially available rare-earth magnetic materials. They exhibit high remanence (Br), high intrinsic coercivity (Hcj), and an excellent maximum energy product (BHmax), capable of generating extremely powerful magnetic fields in compact volumes. These magnets are produced using advanced powder metallurgy sintering technology, with precise control of alloy composition, particle size distribution and magnetic orientation.

2. Technical Parameters

- Product Name: Sintered NdFeb Permanent Magnets

- Magnet Grade: N45(Br ≥ 13.8 KGs, Hcj ≥ KOe)

- Dimensions-Customization

- Dimensional Tolerances: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

- Working Temperature: ≤ 80°C (custom high-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 4500 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 1.8 mWb (measured with fluxmeter)

3. Manufacturing Process

Special-Shaped Cutting: Performed using dedicated non-standard wire-cutting equipment for non-square/non-circular geometric machining.

Grinding & Shaping: Used for complex structures and high-precision contour finishing to ensure dimensional and geometric tolerances.

Demagnetization Treatment: Initial demagnetization followed by precise magnetization to prevent magnetic deviation after assembly.

Laser Engraving & Marking: Marks the N-pole polarity and supports custom patterns or serial numbers as per customer requirements.

4. Surface Treatment & Coating Technology

Epoxy Resin Coating:

Offers additional protection against chemical corrosion and moisture, particularly suitable for high-humidity environments.

Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection Standards

Manual Inspection (Micrometer/Caliper): Ensures dimensional precision and conformance to specification.

Visual Inspection: Conducted under standard lighting to detect visible surface defects or cracks.

2D Vision Measurement System: Used for inspecting non-standard or complex-shaped products to ensure geometric accuracy.

CCD Automatic Sorting Machine: Enables high-speed automated inspection of dimensions and surface appearance, improving production efficiency and reducing human error.

Magnetic Flux Testing: Ensures consistency in magnetic strength across batches, meeting performance requirements.

6. Reliability Testing

Shock & Vibration Testing:

Simulates the stresses encountered during transportation and usage to verify mechanical integrity.

High-Temperature Demagnetization Test:

Evaluates magnetic stability under elevated temperatures to ensure long-term performance.

Damp Heat Testing:

Exposes magnets to high humidity environments to assess moisture resistance and anti-corrosion capability.

7. Packaging & Transportation

Defect Elimination:

Visually and dimensionally defective products are removed.

Magnetization & Arrangement:

Each magnet is uniformly magnetized and arranged neatly according to customer packaging requirements.

Vacuum Packaging:

Protects against moisture and magnetic interference.

Outer Packaging:

Shock-proof, moisture-resistant, and magnetic shielding cartons ensure safe transport and storage.

8. Application Fields

Advanced Medical Devices:

Widely used in MRI systems, magnetic-assisted positioning components, and surgical magnetic fixation systems. These magnets provide stable and controllable magnetic fields to ensure reliability and safety in sensitive medical environments.

Industrial Automation:

Applied in positioning, clamping, and conveying systems on automated production lines, such as magnetic chucks and guide rails, improving assembly precision and system efficiency through non-contact operation.

Smart Wearable Devices:

Integrated into smartwatches, Bluetooth headsets, magnetic charging interfaces, and other wearable accessories, enabling magnetic docking, quick disassembly, and precise alignment, enhancing both user experience and product compactness.

9. Usage Precautions

Handling:

NdFeB magnets are hard but brittle. Avoid dropping, collision, or chipping during transportation or use.

Safe Use:

Due to their strong magnetic force, avoid bending during handling. It is recommended to slide magnets apart to prevent pinching injuries.

Correct Installation:

Identify pole orientation correctly (based on shape) to ensure proper installation and safe equipment operation.

Storage Conditions:

Keep magnets away from high temperatures, humidity, strong acids, and alkalis. Ensure dry and corrosion-free storage.

Magnetic Interference:

Keep away from sensitive electronic equipment such as hard drives, IC cards, and pacemakers due to strong magnetic fields.

10. Customization & Services

Support for customized dimensions, shapes, coating types (layer count, thickness, color)

Customizable magnetic polarity and field strength

Laser engraving for logos or serial numbers available

Tailored packaging and magnetic pull-force testing solutions for special applications.

11. Why choose Jinconn magnet

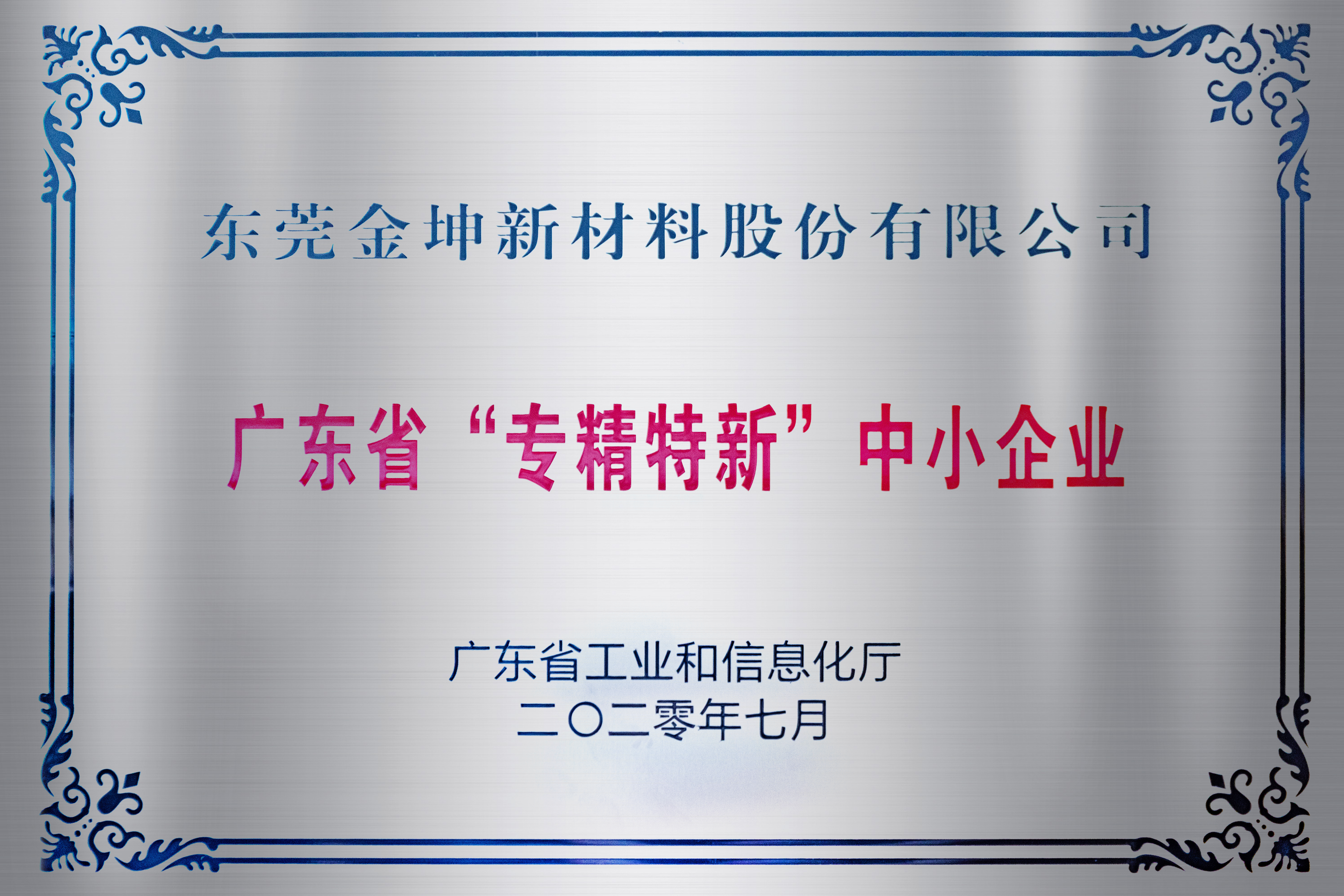

11.1 Company Introduction

Dongguan Jinkun New Materials Holdings Co., Ltd. specializes in the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of “Technology as the foundation, quality as the soul,” the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, support the development of the global intelligent industry, and strive to become a benchmark enterprise and trusted strategic partner in the magnetic materials industry

11.2 Patent

We are dedicated to providing high-performance magnetic material solutions for industries such as new energy vehicles, intelligent manufacturing, and electronic communications. Backed by advanced technology and rigorous quality standards, we are a trusted partner to leading companies worldwide.

We are pleased to offer free customized magnet solutions tailored to your specific needs.

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Product Name: Countersunk NdFeB Magnet

Magnetic Grade: N38M (Br ≥ 12.3 kGs, Hcj ≥ 14 kOe)

Dimensions: D15×10-H6×3mm (customizable)

Tolerance Length/Width/Thickness: ±0.05mm

Operating Temp.: ≤100°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Gauss: 3500 ±200 Gauss (TM-801 meter)

Magnetic Flux: 2.3 mWb (measured)

¥0.00¥0.00 -

-

-

Jinconn WeChat