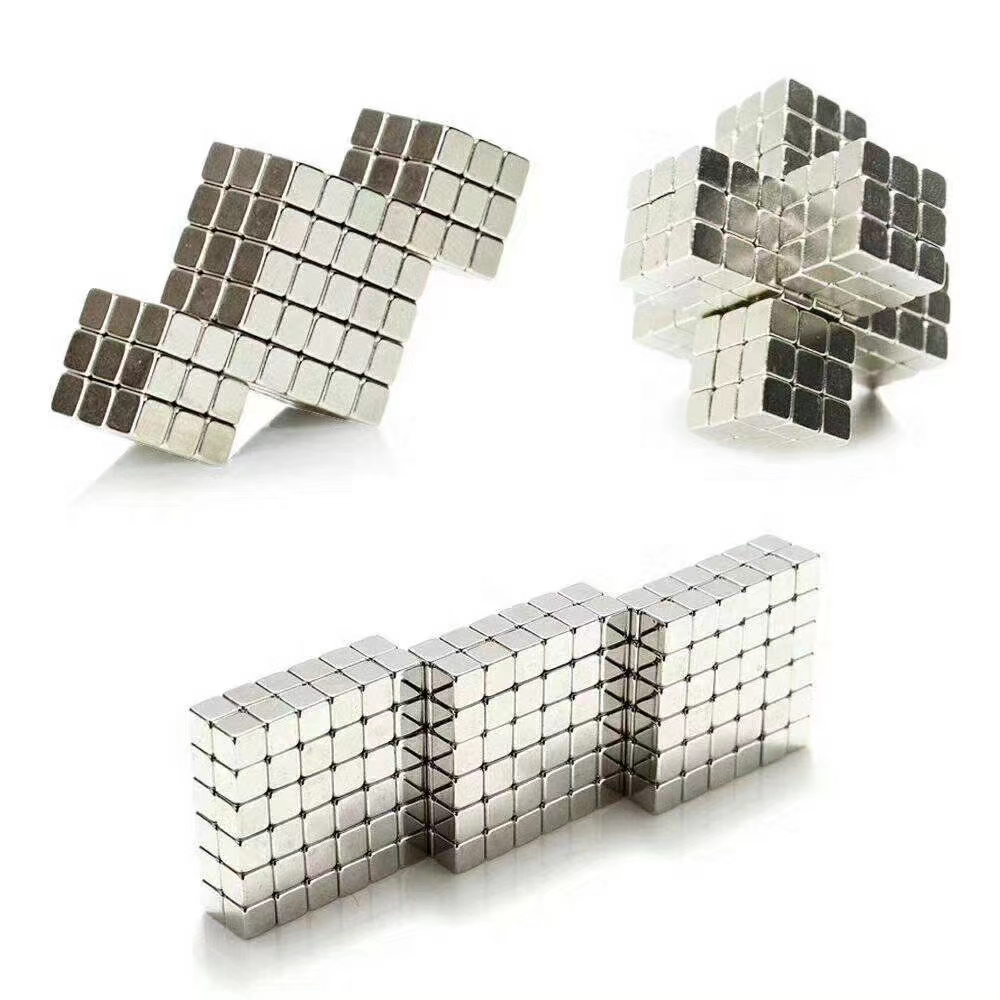

1. Product Overview

Nickel-plated cube magnets feature six magnetizable faces. When axially magnetized, they form closed magnetic circuits, delivering stronger holding force than same-volume bar magnets. The nickel plating provides exceptional corrosion resistance, ideal for marine/chemical environments. Supports single-axis (X/Y/Z) or multi-axis magnetization.

2. Technical Parameters

-Product Name: Nickel Plated Cube Magnet

- Magnet Grade: 42H (Br ≥13.5 kGs, Hcj ≥17 kOe)

- Dimension: 25mm × 5mm × 8mm

- Dimensional Tolerance: L±0.05mm, W±0.05mm, T±0.05mm

- Operating Temperature: ≤120°C (High-temp versions available)

- Density: ≥7.5 g/cm³

- Surface Magnetic Field: 4,300 Gs

- Magnetic Flux : 2.0 mWb (Fluxmeter-tested)

3. Manufacturing Process

- Directional Magnetization:

Pulse magnetizer achieves 99% saturation along specified axes

- Wire Cutting:

Molybdenum wire cutting (±0.03mm accuracy, segmented programming)

4. Surface Treatment & Plating

- Laser Cladding:

Nickel-based alloy fusion at edges → Enhanced hardness

- Cleaning & Degreasing:

Ultrasonic cleaning with alcohol/specialized solvents

- Activation Treatment:

Immersion in dilute HCl/H₂SO₄ → Improved coating adhesion

5. Appearance & Dimensional Inspection

- Visual inspection: 800-1,200 Lux, 20-750px distance

- 2D optical measurement: Irregular/non-standard structures

- CCD sorting: Automated full inspection

6. Reliability Testing

Magnetic Performance:

- Field strength mapping (Gauss meter)

- Stability under thermal/humidity aging

Physical Properties:

- Hardness (Rockwell/Vickers testers)

- Density measurement

- Dimensional accuracy (micrometer/caliper)

Environmental Adaptability:

- Temperature cycling: -40°C to +80°C

- Humidity: >90% RH exposure

- Salt spray: ASTM B117

7. Packaging Process

-Reject defective items

-Magnetize & align conforming products

-Custom quantitation/labeling per box

-Individual vacuum sealing

8. Application Fields

Industrial Manufacturing

- Machining & Fixturing:

Workpiece fixturing in CNC/welding; magnetic bases for tooling

- Automation & Conveyance:

Metal part handling (gears/bolts); magnetic separators

- Motors & Sensors:

Stepper motor PMs; proximity switches/encoders

Electronics & Communication

- Consumer Electronics:

MagSafe interfaces; headphone/speaker drivers

- RF Devices:

Antenna/filter components; EMI shielding

Medical & Research

- Surgical tools (laparoscopic retrieval)

- MRI auxiliary magnets; centrifuge rotors

9. Usage Precautions

- Mechanical: Impact protection; no press-fit assembly

- EM Safety: >750px from pacemakers/sensitive devices

- Performance: Never exceed Curie temperature; avoid reverse magnetization

10. Customization & Services

- Dimensions/shapes/coatings

- Polarity/magnetic strength customization

- Laser marking (logos/serial numbers)

- Application-specific encapsulation & pull-force testing

11.Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd. focuses on the research, development, production, and sales of high-performance magnetic materials. Upholding the philosophy of "Technology as the foundation, Quality as the soul," the company is committed to becoming a global leader in magnetic material solutions.

Its products are widely applied in new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad.

11.2 Target Audience

Samples, datasheets, MSDS, RoHS, ISO9001, QC08000, IATF16949, ISO14001, ISO27001

For customized magnet services, please contact us!

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

-

Square High-Performance NdFeB Magnet

Product Name: Square High-Performance NdFeB Magnet

Material Grade: N35 (Remanence Br ≥12.3 kGs, Intrinsic Coercivity Hcj ≥10.8 kOe)

Dimensions: L10×5×3mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2500±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.0 mWb (measured with flux meter)¥0.00¥0.00 -

-

Jinconn WeChat