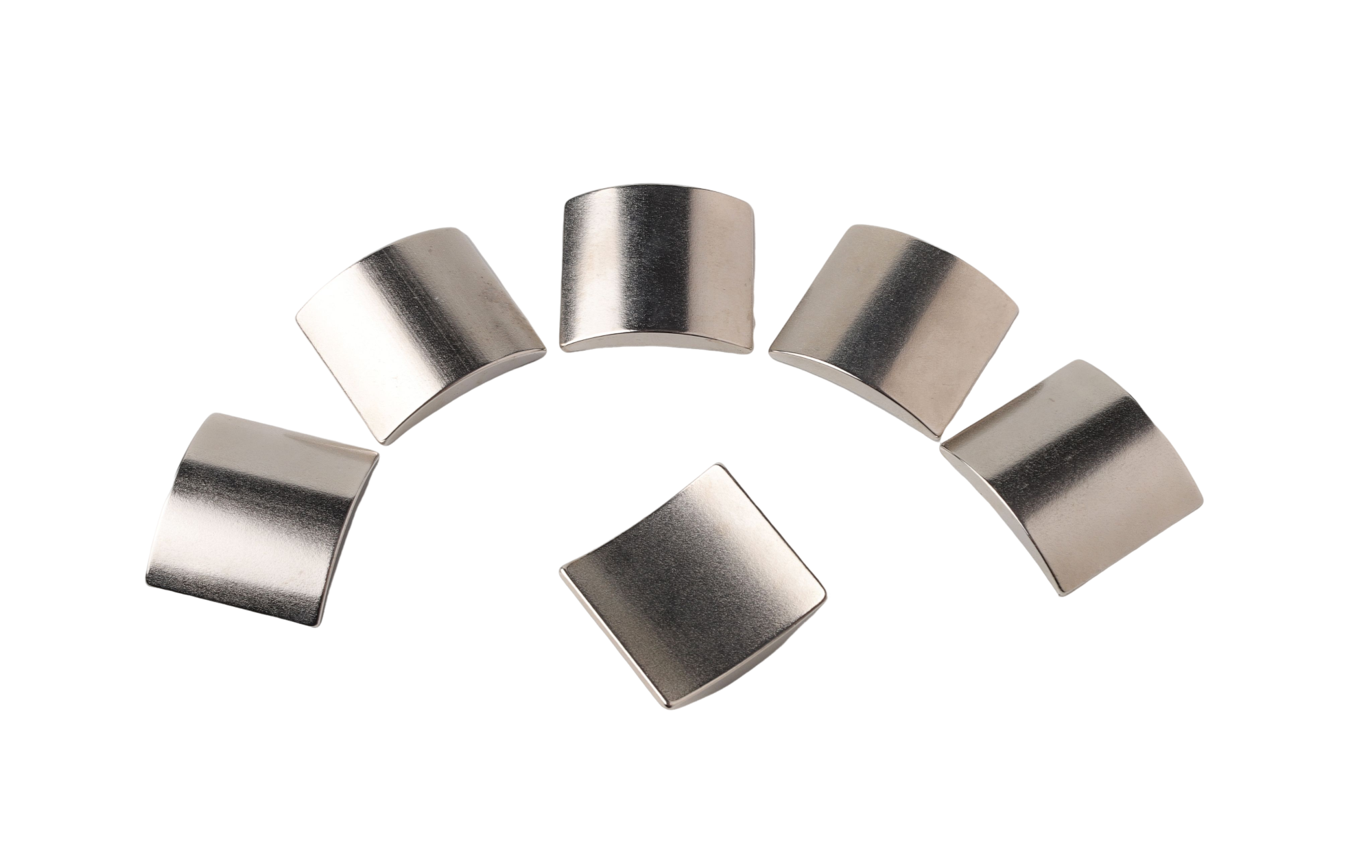

1. Product Overview

Tile-shaped NdFeB permanent magnets are made from NdFeB (Neodymium Iron Boron) alloy, offering extremely high magnetic energy product and high-intensity magnetic fields. They are widely used in high-performance motors, sensors, magnetic couplings, and other applications. Their tile shape design is better suited for mechanical structures or magnetic field control requirements, providing stable and powerful magnetic output. The performance advantages of NdFeB permanent magnets under high-temperature and high-field conditions make them crucial in industrial applications.

2. Technical Parameters

- Product Name: Tile-shaped permanent NdFeB rare earth magnet

- Magnet Grade: N42 (Br ≥ 13.5 KGs, Hcj ≥ 12 KOe)

- Dimensions:R20*R18*14*2.5

- Tolerances:Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

- Working Temperature: ≤ 80°C (custom high-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 2500 ± 200 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 1.30 mWb (measured with fluxmeter)

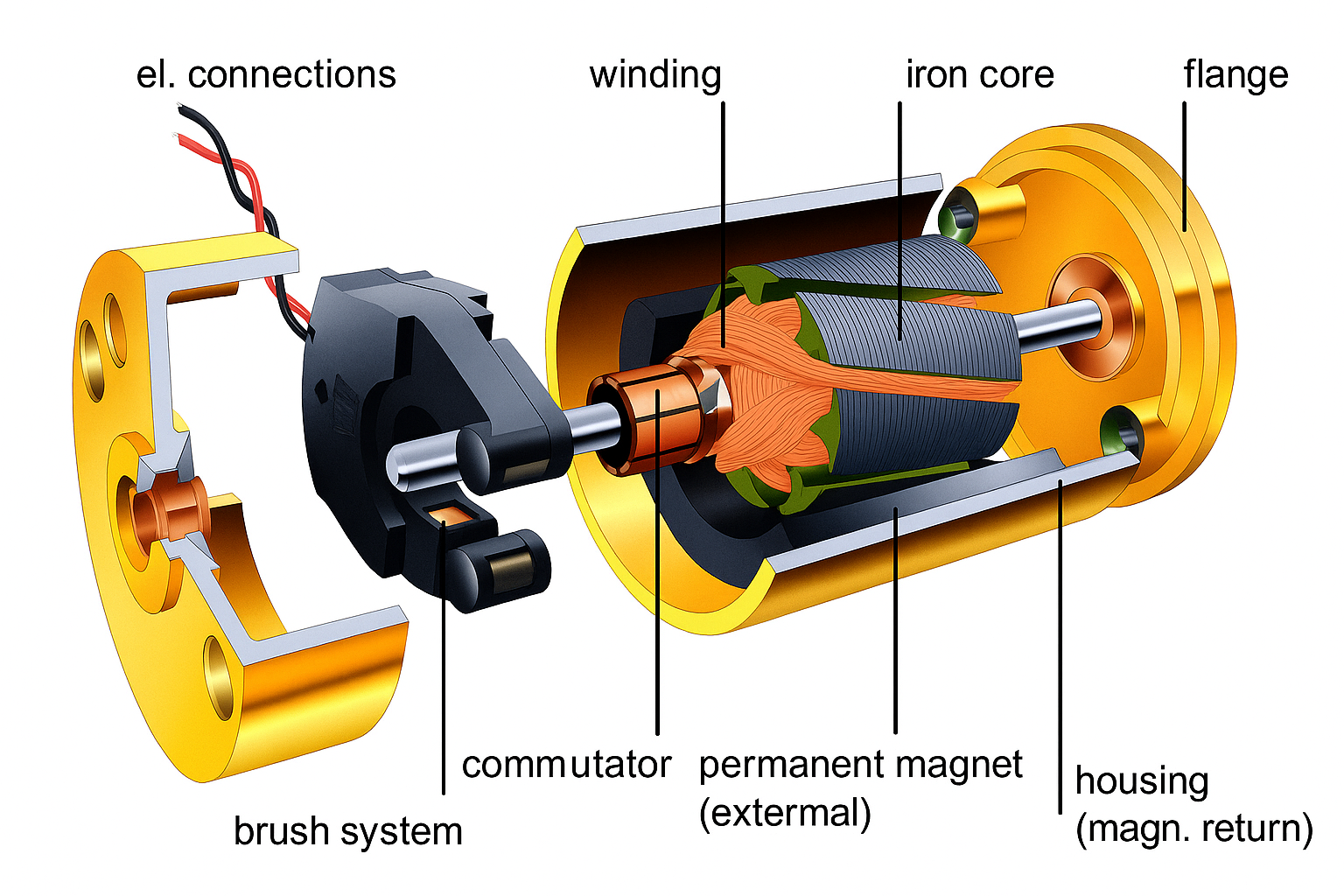

3. Manufacturing Process

Special-Shaped Cutting: Custom wire-cutting equipment for non-square/non-circular geometries.

Grinding Wheel Molding: Ensures complex structures and high-precision shaping.

Magnetization Process: After all physical processing steps, the magnet enters the magnetization stage. Professional pulse magnetization equipment charges the magnet with a strong and stable magnetic field, ensuring the magnet meets design standards and works stably in high-load or high-frequency environments. This step is critical to achieving the best performance and long-lasting magnetic output for each magnet.

4. Surface Treatment & Coating Technology

Epoxy Resin Coating: Provides additional chemical corrosion and waterproofing properties, especially suitable for environments with high humidity.

Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection Standards

Manual Dimensional Inspection: Using micrometers or calipers to ensure dimensional accuracy, guaranteeing that each product meets the required specifications.

Visual Inspection: Inspecting the surface of the magnet under standard lighting to ensure no visible defects or cracks.

2D Imaging Measurement System: Used to inspect non-standard or complex shapes, ensuring the shape and size are accurate.

Magnetic Flux Testing: Ensuring that each batch of magnets has consistent magnetic force, meeting the design requirements.

6. Reliability Testing

Impact & Vibration Testing: Simulates the impact and vibration during transportation and usage to ensure the reliability of the magnet in working environments。

High-Temperature Demagnetization Testing: Verifies the magnetic stability of the magnet under high-temperature conditions, ensuring its stable performance over long-term use.

Humidity Testing: Exposing the magnet to high humidity environments to check its resistance to moisture and corrosion.

7. Packaging & Shipping

Rejection of Defective Products: Products that do not meet appearance or dimensional standards are rejected.

Magnetization & Neat Arrangement: Ensures each magnet is uniformly magnetized and arranged according to customer requirements for packaging.

Vacuum Packaging: The magnets are vacuum-packed to protect them from moisture and magnetic interference.

Outer Packaging: The outer packaging is designed to be impact-resistant, moisture-proof, and magnetic interference-shielded to ensure safety during transportation.

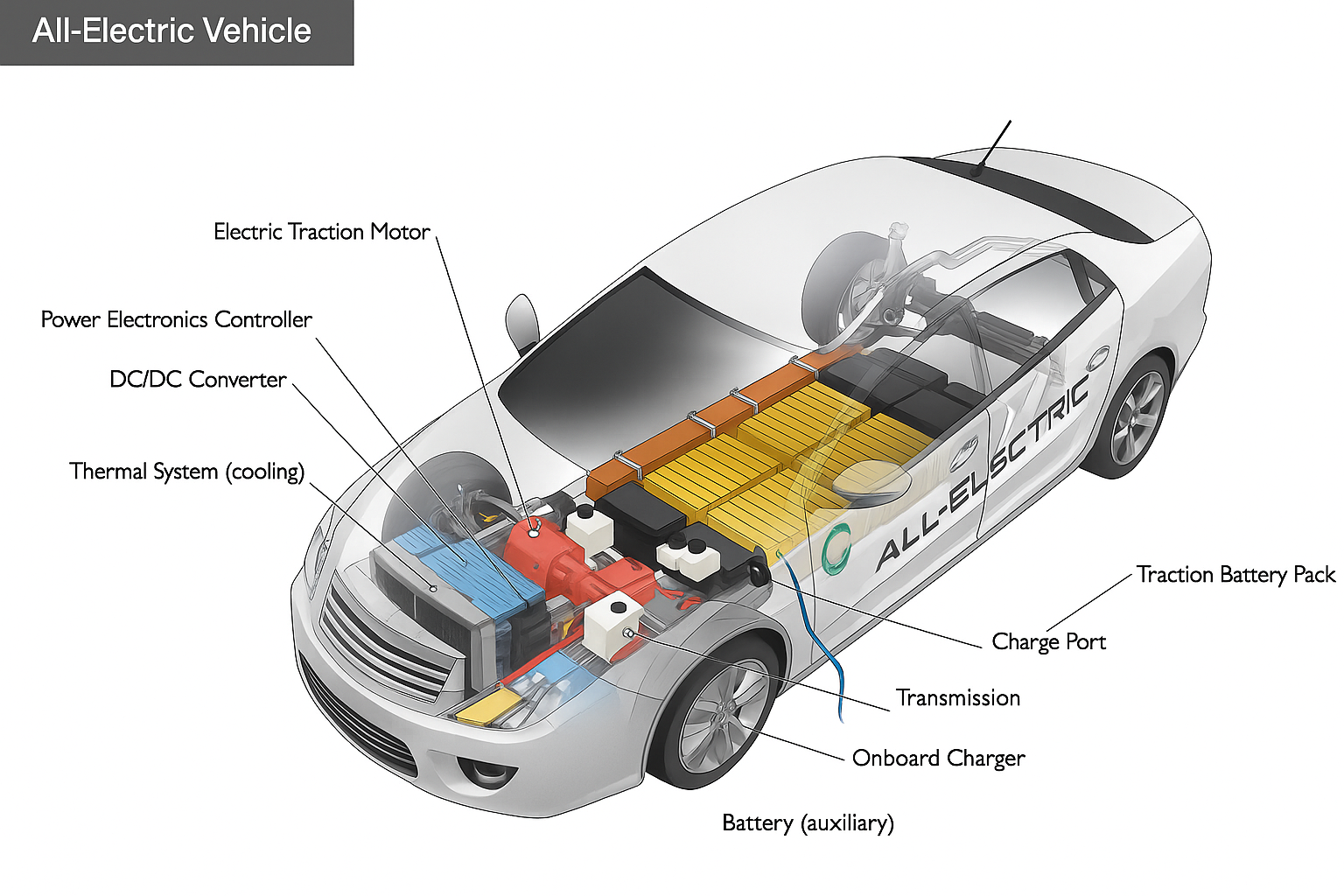

8. Application Fields

Brushless Motor Systems: Used in rotor systems for electric tools, electric vehicle drive systems, servo motors, etc., providing stable magnetic field output.

Sensors & Measurement Devices: Widely used in displacement sensors, Hall sensors, encoders, and other devices to provide accurate position and speed feedback.

High-End Medical Equipment: Used in MRI auxiliary components and magnetic fixtures, providing stable magnetic force.

Industrial Automation: Used in positioning and clamping systems in automated production lines to ensure efficient assembly.

Smart Wearables: Used in magnetic components for smartwatches, earphones, and other products.

9. Usage Precautions

Handling: NdFeB material is hard but brittle; avoid dropping, collision, or damage during handling.

Safe Use: Due to its strong magnetic properties, avoid bending the magnets; use sliding motions to handle them safely and avoid pinching.

Correct Installation: Identify the polarity based on the larger end of the magnet and install correctly to ensure the device operates smoothly.

Storage: Store the magnets in a dry, moisture-proof environment away from strong acids, bases, or high-temperature conditions.

Magnetic Protection: Keep magnets away from hard disks, IC cards, pacemakers, and other sensitive equipment due to their strong magnetic fields.

10. Customization & Services

Customization: Available for size, shape, coating (number of layers, thickness, color), and magnetic direction.

Laser Engraving: Logos or serial numbers can be engraved on the magnets.

Sample Testing & Pull Force Testing: Available to meet specific application requirements.

Documentation: Certifications including MSDS, RoHS, ISO9001, and others can be provided upon request.

11.Why choose Jinconn magnet / what jinconn offers

11.1 Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd. is committed to the research, development, production, and sales of high-performance magnetic materials. Guided by the philosophy of "Technology as the foundation, Quality as the soul," the company strives to become a global leader in magnetic material solutions.

Our products are widely used in various fields, including new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, and have earned the trust of customers both at home and abroad.

11.2 Target Customer

We are pleased to offer free customized magnet solutions tailored to your specific needs.

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Product Name: Countersunk NdFeB Magnet

Magnetic Grade: N38M (Br ≥ 12.3 kGs, Hcj ≥ 14 kOe)

Dimensions: D15×10-H6×3mm (customizable)

Tolerance Length/Width/Thickness: ±0.05mm

Operating Temp.: ≤100°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Gauss: 3500 ±200 Gauss (TM-801 meter)

Magnetic Flux: 2.3 mWb (measured)

¥0.00¥0.00 -

High-Performance Tile-Shaped NdFeB Magnet

Product Name: High-Performance Tile-Shaped NdFeB Magnet

Material Grade: N48SH (Remanence Br ≥ 14.2 kGs, Intrinsic Coercivity Hcj ≥ 20 kOe)

Dimensions: R16R14.156.15.51.5mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤150℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2800±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.1 mWb (measured with flux meter)¥0.00¥0.00 -

-

Jinconn WeChat