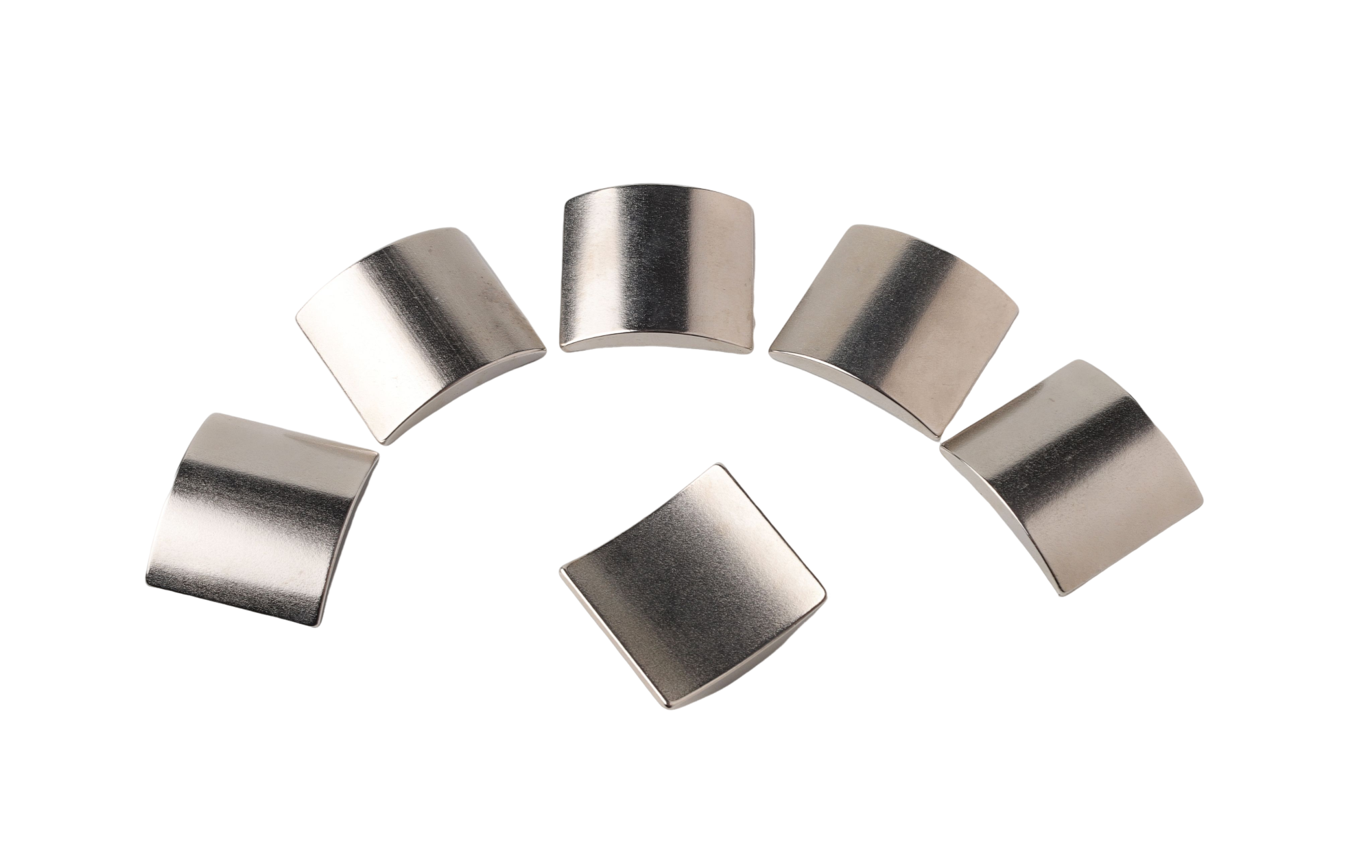

1. Product Overview

The special-shaped arc magnet is a curved permanent magnet custom-designed to match specific spatial structures. Formed through precise sintering or cutting using custom molds, it offers seamless integration with complex surfaces that standard block magnets cannot match. Owing to its excellent spatial adaptability and precise magnetic circuit control, it serves as a key component in high-efficiency electromagnetic systems.

2. Technical Parameters

- Product Name: Special-Shaped Arc Magnet

- Magnet Grade: 38H (Br ≥ 12.9 KGs, Hcj ≥ 11.4 KOe)

- Dimensions: R45 × R40 × 15 × 4 mm

- Tolerances: ±0.05 mm in length, width, and thickness

- Working Temperature: ≤ 120°C (high-temperature versions customizable)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 4200 Gauss ± 200 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 3.3 mWb (measured with fluxmeter)

3. Manufacturing Process

Special-Shaped Cutting: Performed using dedicated non-standard wire-cutting equipment for non-square/non-circular geometric machining.

Grinding & Shaping: Used for complex structures and high-precision contour finishing to ensure dimensional and geometric tolerances.

4. Surface Treatment & Coating Technology

To enhance corrosion resistance and appearance:

Default Plating: Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection Standards

- Manual dimensional inspection using micrometers/calipers

- Visual inspection under 800–1200 lumen lighting (20–30 cm distance)

- 2D optical measurement for irregular or non-standard shapes

6. Reliability Testing

- Humidity Test: Exposure to environments with >90% relative humidity to assess rust, corrosion, and magnetic degradation.

- Salt Spray Test: Simulates coastal environments to evaluate corrosion resistance.

- Impact Test: Simulates handling or transportation shocks to check for cracks or breakage.

- Vibration Test: Magnet is fixed to a vibration platform and tested at varying frequencies/amplitudes to assess reliability.

7. Packaging Process & Instructions

- Elimination of defective products based on appearance and dimensions

- Magnetization and aligned arrangement of qualified magnets

- Boxed by quantity with custom labeling per client specifications

- Each box vacuum-sealed with magnetic shielding and anti-shock padding

- Boxes packed into outer cartons with moisture, impact, and EMI protection

(Custom packaging available)

8. Application Fields

- Motor Engineering: Brushless DC motors – improves torque density and reduces eddy current loss

- Automotive Electronics: Power steering motors, ABS sensors – high temperature and vibration tolerance, improved signal stability

- Medical Devices: MRI systems, miniature pump magnetic drives – non-magnetic interference, biocompatible coatings

- Energy Equipment: Wind turbine pitch systems – anti-corrosion in salt fog (C5 protection level)

9. Usage Precautions

- Handle with care: NdFeB material is hard but brittle; avoid dropping or impact during handling

- Safety: Due to strong magnetism, do not bend; slide magnets apart to avoid pinching

- Correct Installation: Identify and install according to polarity to ensure proper operation

- Storage: Avoid high temperature, humidity, and corrosive environments

- Isolation: Keep away from magnetic-sensitive devices such as HDDs, IC cards, and pacemakers

10. Customization & Services

- Custom options for dimensions, shape, coating layers, thickness, and color

- Customizable magnetic orientation and strength

- Laser engraving for logos or serial numbers available

- Application-specific packaging and pull-force testing solutions available

11. Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd specializes in the research, development, production, and sales of high-performance magnetic materials. Upholding the core philosophy of "Technology as the foundation, Quality as the soul," the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in cutting-edge fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning strong recognition and trust from clients both domestically and internationally.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

High-Performance Ring-Shaped Neodymium Magnet

Product Name: Ring-shaped high-performance rare earth neodymium magnet

Material Grade: N52 (Br ≥ 14.2 kGs, Hcj ≥ 12 kOe)

Dimensions: D20-D17×2 mm (custom sizes available)

Dimensional Tolerance: ±0.05 mm (length/width/thickness)

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 3000 ± 200 Gauss (measured with Japanese TM-801 Gauss meter)

Magnetic Flux Value: 2.1 mWb (measured with fluxmeter)

¥0.00¥0.00 -

Custom-Shaped High-Performance Rare Earth Neodymium Magnet(1)

Product Name: Custom-Shaped High-Performance Rare Earth Neodymium Magnet

Material Grade: N52M (Br ≥ 14.2 kGs, Hcj ≥ 14 kOe)

Dimensions: Y9.5 × 7 × 5 mm (custom sizes available)

Dimensional Tolerance: Length ±0.04 mm, Width ±0.04 mm, Thickness ±0.05 mm

Operating Temperature: ≤100℃ (high-temp versions customizable)

Density: ≥7.5 g/cm³

Magnetic Pole Marking: N pole laser engraved (custom graphics available; for stringent salt spray resistance, inkjet or scribed markings can be used)

Surface Magnetic Field: 5300 ± 200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux: 2.3 mWb (measured with fluxmeter)¥0.00¥0.00 -

High-Performance Custom-Shaped Neodymium Magnet

Product Name: Custom-shaped high-performance rare earth neodymium magnet

Material Grade: N52 (Br ≥ 14.2 kGs, Hcj ≥ 12 kOe)

Dimensions: Y12 × 5 × 8 mm (custom sizes available)

Dimensional Tolerance: Length ±0.05 mm, Width ±0.05 mm, Thickness ±0.05 mm

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Magnetic Pole Marking: N-pole laser engraving for easy assembly identification. Custom marking patterns available. For high salt spray resistance requirements, inkjet or scribed markings can be used as N-pole identifiers.

Surface Magnetic Field: 5000 ± 200 Gauss (measured with Japanese TM-801 Gauss meter)

Magnetic Flux Value: 2.3 mWb (measured with fluxmeter)

¥0.00¥0.00 -

High-Performance Tile-Shaped NdFeB Magnet

Product Name: High-Performance Tile-Shaped NdFeB Magnet

Material Grade: N48SH (Remanence Br ≥ 14.2 kGs, Intrinsic Coercivity Hcj ≥ 20 kOe)

Dimensions: R16R14.156.15.51.5mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤150℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2800±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.1 mWb (measured with flux meter)¥0.00¥0.00

Jinconn WeChat