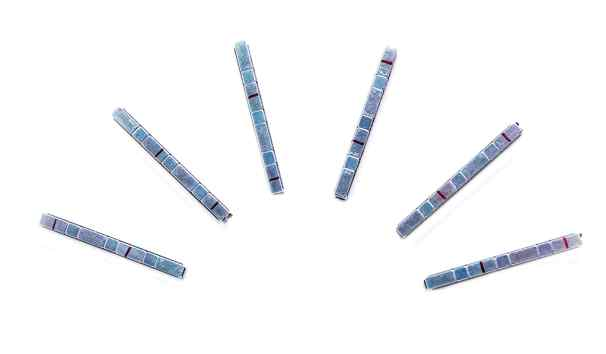

1. Product Overview

Specialized NdFeB magnets engineered for wireless charging systems, delivering exceptional magnetic strength in compact form factors while maintaining superior stability. Widely used in portable devices including smartphones, earbuds, and smartwatches. Customization options include dimensions, shapes, coatings, and polarity configurations to meet the diverse requirements of end products.

2. Technical Parameters

Product Name: Wireless Charging Magnet

Magnet Grade: N45 (Br ≥13.8 kGs, Hcj ≥10.8 kOe)

Dimensions: L12mm × 4mm × 2mm (Customized)

Dimensional Tolerance:Length±0.05mm, Width±0.05mm, Thickness±0.05mm

Operating Temperature: ≤80°C (High-temp version customized)

Density≥7.5 g/cm³

Surface Magnetic Field: 4,500 Gs (single magnet)

Magnetic Field : 1.80 mWb (measured by fluxmeter)

3. Manufacturing Process

Special-Shaped Cutting: Performed using dedicated non-standard wire-cutting equipment for non-square/non-circular geometric machining.

Grinding & Shaping: Used for complex structures and high-precision contour finishing to ensure dimensional and geometric tolerances.

Demagnetization Treatment: Initial demagnetization followed by precise magnetization to prevent magnetic deviation after assembly.

Laser Engraving & Marking: Marks the N-pole polarity and supports custom patterns or serial numbers as per customer requirements.

4. Surface Treatment & Plating

To enhance corrosion/wear resistance:

Default Plating: Triple-layer Ni-Cu-Ni (customized)

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm) (customized)

5. Appearance & Dimensional Inspection

All products undergo strict QC:

Manual inspection (micrometer/caliper)

Visual inspection (800-1200 lux, 20-750px distance)

2D optical measurement (for irregular geometries)

CCD automated sorting & full inspection

Flux testing (batch consistency verification)

6. Reliability Testing

6.1 Neutral Salt Spray Test (NSS)

Temperature: 35°C ±2°C

Salt settlement: 1-2 ml/2000px² per hour

pH: 6.5–7.2

Duration: 12h/24h/48h (customized)

6.2 Temperature Demagnetization Test

80°C oven for 2h (customized duration)

Demagnetization rate ≤10% = Pass

- Simulates real-world thermal stability.

7. Packaging Process

Professional magnetic-safe packaging:

Comprehensive inspection (magnetic properties, dimensions, appearance)

Uniform magnetization and alignment

Custom quantitation/labeling per box

Vacuum sealing + magnetic shielding/buffer pads

Master cartons with moisture, collision, and interference protection

(Custom packaging available)

8. Application Fields

Consumer Electronics: Magnetic-attach charging, foldable screen hinge charging

Smart Mobility: In-vehicle phone charging, new energy vehicles

9.Usage Precautions

Prevent impact and dropping

Reject defective products( appearance/dimensions)

Uniformly magnetize passed items and arrange neatly

Quantitative boxing and Quantitative labels

Vacuum packaging with magnetic-proof spacers and cushion pads

10. Customization & Services

We support:

Dimensions/shape/plating (layers, thickness, color)

Polarity & magnetic strength adjustments

Laser marking (logos/serial numbers)

Special encapsulation & pull-force testing

Request samples, datasheets (MSDS/RoHS), or certifications (ISO9001, IATF16949, etc.) from sales engineers.

11.Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd specializes in the research, development, production, and sales of high-performance magnetic materials. Upholding the core philosophy of "Technology as the foundation, Quality as the soul," the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in cutting-edge fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning strong recognition and trust from clients both domestically and internationally.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

-

Product Name: NdFeB Magnet Halbach Array

Magnetic Grade: N35 (Br ≥ 12.3 kGs, Hcj ≥ 10.8 kOe)

Dimensions: L50×5×5mm (customizable)

Dimensional Tolerance Length: ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4500 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (measured with fluxmeter)¥0.00¥0.00 -

Jinconn WeChat