1. Product Overview

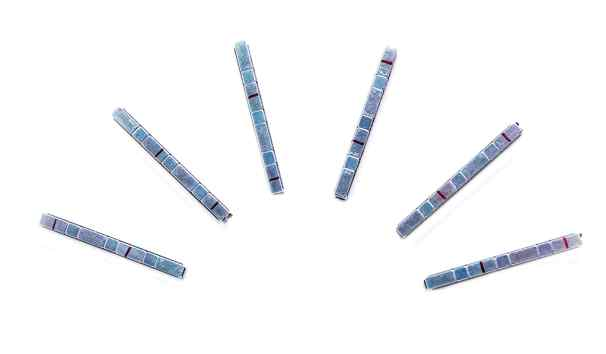

This magnet is a high-performance NdFeB Halbach Array configured in a specialized arrangement. With a magnet grade of N52, it provides exceptional magnetic strength and performance. It also boasts superior dimensional accuracy and can be tailored to fulfill specific customer needs. Through optimized directional magnetization, this array markedly boosts magnetic field intensity on one side while effectively diminishing it on the opposite side,making it widely suitable for applications requiring a strong unilateral magnetic field.

2. Technical Parameters :

Product Name: Halbach Array

Magnet Grade: N52 (Br ≥14.8 kGs, Hcj ≥10.5 kOe)

Dimensions: L20 × 13 × 3.5mm (customized)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (High-temperature version available)

Density: ≥7.5 g/cm³

Surface magnetic Field: 5400 ±200 Gauss(Measured withTM-801 Gauss Meter)

Magnetic field : 2.0 mWb (Tested by fluxmeter)

3. Manufacturing Process:

Key production steps include:

Directional Magnetization: Sequential pulse magnetization is achieved using multi-pole magnetizing heads, with a 90° magnetic field difference between adjacent magnets.

Bonding & Curing: Stabilization through high-temperature epoxy structural adhesive or vacuum pressure curing.

4. Surface Treatment & Plating

To enhance corrosion resistance, appearance, and magnetic stability:

Edge Reinforcement: Laser-clad nickel-based alloy at seams

(preventing electrochemical corrosion).

Edge Rounding: Minimizes magnetic field distortion.

Default Plating: Triple-layer Ni-Cu-Ni plating.

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm) (Customized).

Optional Plating: precious metal (Au/Ag) for superior conductivity and corrosion resistance.

Features:

✔ Salt spray resistance & oxidation prevention

✔ Increased surface hardness (scratch-resistant)

✔ Improved gloss (suitable for exposed components)

5. Appearance & Dimensional Inspection

All products undergo strict QC:

Manual caliper/micrometer measurement

Visual inspection (800–1200 lux, 20–750px distance)

2D imaging measurement (for complex shapes)

CCD sorting machine (auto-checking dimensions/appearance)

Magnetic flux testing (batch consistency)

6. Reliability Testing

6.1 Neutral Salt Spray (NSS) Test

- Temperature: 35°C ±2°C

- Salt dposition 1-2 ml/2000px². hour

- pH: 6.5–7.2

- Duration: 12h/24h/48h (customized)

6.2 Temperature Demagnetization Test

80°C oven for 2h (customized duration)

Demagnetization rate ≤10% = Pass

- Simulates real-world thermal stability.

6.3 Drop Test Note

⚠ Not suitable for impact tests (NdFeB is brittle—may chip/crack).

7. Packaging Process

Quality Screening

Firstly, conduct appearance and size inspection on products, strictly eliminating defective items to ensure only qualified products enter the packaging process.

Magnetization and Arrangement

Uniformly magnetize the qualified products, then neatly arrange them according to standard specifications, providing an orderly basis for subsequent packaging.

Customized Packaging

Carry out quantitative boxing according to customer needs, and customize exclusive labels to achieve personalized matching of packaging specifications and identification.

Protective Packaging

Each box of products is vacuum-packed, with magnetic-proof partitions and cushioning shock-proof pads built in, providing dual protection against magnetic interference and transportation collisions.

Overall Boxing

Load the small boxes into outer cartons. The overall packaging has functions of moisture-proof, collision-proof and magnetic interference-proof, ensuring safety and reliability during transportation.

8. Application Fields

Widely used in:

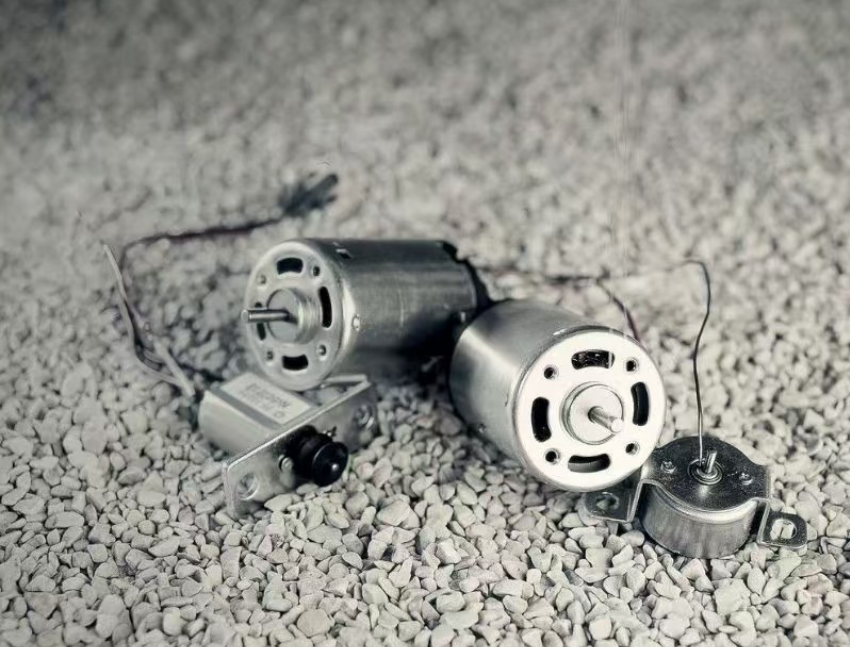

High-Precision Motors: Coreless motors, linear motors

Magnetic Levitation: Superconducting maglev trains, vacuum tube transport

Medical/Detection: Portable MRI, electron microscope lenses

Industrial Automation: 3D printing magnetic nozzles, magnetic encoders

9. Usage Precautions

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10. Customization & Services

We support:

Dimensions/shape/plating (layers, thickness, color)

Polarity & magnetic strength adjustments

Laser marking (logos/serial numbers)

Special encapsulation & pull-force testing

Request samples, datasheets (MSDS/RoHS), or certifications (ISO9001, IATF16949, etc.) from sales engineers.

11. Why choose Jinconn magnet

11.1 Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd. specializes in the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of “Technology as the foundation, quality as the soul,” the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, support the development of the global intelligent industry, and strive to become a benchmark enterprise and trusted strategic partner in the magnetic materials industry

11.2 Patent

We are dedicated to providing high-performance magnetic material solutions for industries such as new energy vehicles, intelligent manufacturing, and electronic communications. Backed by advanced technology and rigorous quality standards, we are a trusted partner to leading companies worldwide.

We are pleased to offer free customized magnet solutions tailored to your specific needs.

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

-

Product Name: NdFeB Magnet Halbach Array

Magnetic Grade: N35 (Br ≥ 12.3 kGs, Hcj ≥ 10.8 kOe)

Dimensions: L50×5×5mm (customizable)

Dimensional Tolerance Length: ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4500 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (measured with fluxmeter)¥0.00¥0.00 -

Jinconn WeChat