1. Product Overview

NdFeB rectangular magnets deliver ultra-high magnetic energy density, flexible shape adaptability, and exceptional dynamic response, making them indispensable core components in precision electromechanical systems. They meet specific dimensional requirements across diverse applications. Compared to other high-performance permanent magnets, NdFeB offers superior resource availability and optimal cost-performance balance.

2. Technical Parameters:

- Product Name: NdFeB Bar Magnets

- Magnet Grade: N52 (Br ≥14.8 kGs, Hcj ≥10.5 kOe)

- Dimensions: 20mm × 7mm × 4mm

- Dimensional Tolerances: L±0.05mm, W±0.05mm, T±0.05mm

- Operating Temperature: ≤80°C (High-temp versions customizable)

- Density ≥7.5 g/cm³

- Surface Magnetic Field: 4,200 Gs ±200 Gs (TM-801 Gauss Meter)

- Flux Value: 2.0 mWb (Fluxmeter-tested)

3. Manufacturing Process

Special-Shaped Cutting: Performed using dedicated non-standard wire-cutting equipment for non-square/non-circular geometric machining.

Grinding & Shaping: Used for complex structures and high-precision contour finishing to ensure dimensional and geometric tolerances.

Demagnetization Treatment: Initial demagnetization followed by precise magnetization to prevent magnetic deviation after assembly.

Laser Engraving & Marking: Marks the N-pole polarity and supports custom patterns or serial numbers as per customer requirements.

4. Surface Treatment & Plating

- Electroless Nickel Plating:

Autocatalytic Ni-P alloy deposition →Superior uniformity/low porosity.

5. Appearance & Dimensional Inspection

Quality assurance protocols:

- Manual inspection (micrometer/caliper)

- Visual inspection (800-1,200 lux, 20-750px distance)

- 2D optical measurement (for irregular geometries)

6. Reliability Testing

6.1 Environmental Adaptability

- Temperature: -40°C to +80°C thermal cycling

- Humidity: >90% RH exposure (corrosion/magnetic stability)

- Salt Spray: ASTM B117 compliance testing

6.2 Mechanical Performance

- Impact Test: Simulated transportation shocks

- Vibration Test: Variable frequency/amplitude assessment

7. Packaging Process:

Magnetic-safe packaging:

-Reject appearance/dimensional defects

-Uniform magnetization & alignment

-Custom quantitation/labeling per box

-Vacuum sealing + magnetic shielding/buffer pads

-Master carton: Moisture/collision/interference protection

(Custom packaging available)

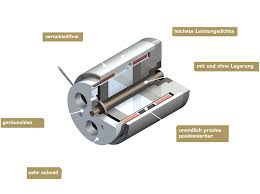

8. Application Fields

- Motors & Drives: Voice coil motors, linear motors

- Sensing & Detection: Position sensors, magnetic encoders

- Industrial: Magnetic separator matrices

- Medical/Research: Particle accelerators, surgical robots

- Consumer Electronics: Smart home devices, TWS earbuds

9. Usage Precautions

- Handling: Avoid drops/impacts (brittle material).

- Safety: Use sliding motion during assembly (pinch hazard).

- Installation: Verify polarity via size markings.

- Storage: Keep dry; avoid heat/acids/alkalis.

- Isolation: Maintain >750px distance from pacemakers/HDDs/IC cards.

10. Customization & Services:

- Dimensions/shapes/coatings (layers, thickness, color)

- Polarity/magnetic strength customization

- Laser marking (logos/serial numbers)

- Application-specific encapsulation & pull-force testing

11. Why choose Jinconn magnet

11.1 Company Introduction

Dongguan Jinkun New Materials Holdings Co., Ltd. specializes in the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of “Technology as the foundation, quality as the soul,” the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, support the development of the global intelligent industry, and strive to become a benchmark enterprise and trusted strategic partner in the magnetic materials industry.

11.2 Patent

We are dedicated to providing high-performance magnetic material solutions for industries such as new energy vehicles, intelligent manufacturing, and electronic communications. Backed by advanced technology and rigorous quality standards, we are a trusted partner to leading companies worldwide.

We are pleased to offer free customized magnet solutions tailored to your specific needs.

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Product Name: NdFeB Magnet Halbach Array

Magnetic Grade: N35 (Br ≥ 12.3 kGs, Hcj ≥ 10.8 kOe)

Dimensions: L50×5×5mm (customizable)

Dimensional Tolerance Length: ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4500 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (measured with fluxmeter)¥0.00¥0.00 -

Jinconn WeChat