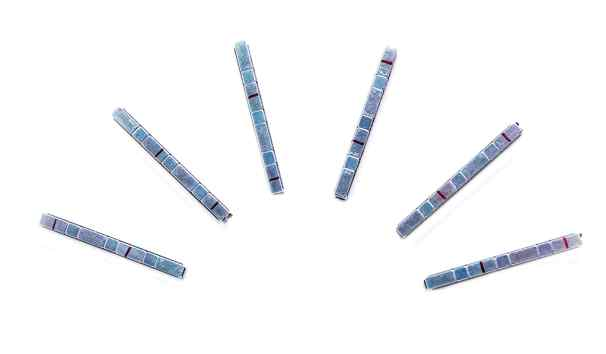

Product Name: NdFeB Magnet Halbach Array

Magnetic Grade: N35 (Br ≥ 12.3 kGs, Hcj ≥ 10.8 kOe)

Dimensions: L50×5×5mm (customizable)

Dimensional Tolerance Length: ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4500 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (measured with fluxmeter)

1. Product Overview

This magnet is a high-performance NdFeB Halbach Array, with a grade of N35, offering high magnetic strength, strong demagnetization resistance, and precise dimensional accuracy. Customized precision is available upon request. Its complex-shaped design meets high-performance magnetic requirements in compact spaces, widely used in applications such as:

Motors/Generators: High-power-density motors (drones, robotics), maglev wind turbines.

Magnetic Levitation: Maglev trains, bearingless flywheel energy storage.

Scientific Equipment: Particle accelerators, nuclear magnetic resonance (NMR).

Medical: MRI imaging, targeted drug delivery.

Industrial: Magnetic refrigeration, wireless charging (EVs).

Consumer Electronics: High-end speakers, magnetic sensors.

Aerospace/Defense: Satellite attitude control, plasma confinement.

Manufactured using advanced wire-cutting technology, the magnet ensures sharp edges and uniform dimensions. Surface treatment includes multi-layer metal plating (Ni+Cu+Ni) or optional Zn plating, effectively preventing oxidation and corrosion, extending service life.

2. Technical Parameters

Product Name: NdFeB Magnet Halbach Array

Magnetic Grade: N35 (Br ≥ 12.3 kGs, Hcj ≥ 10.8 kOe)

Dimensions: L50×5×5mm (customizable)

Dimensional Tolerance Length: ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4500 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (measured with fluxmeter)

3. Manufacturing Process

Wire Cutting: Molybdenum wire cutting for step contours (±0.03mm precision, segmented programming).

4. Surface Treatment & Plating

To enhance corrosion resistance and appearance:

Default Plating: Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Precious metals (Au/Ag) for superior conductivity and corrosion resistance.

Features:

✔ Salt spray resistance & oxidation prevention

✔ Increased surface hardness (scratch-resistant)

✔ Improved gloss (suitable for exposed components)

5. Appearance & Dimensional Inspection

All products undergo strict QC:

Manual caliper/micrometer measurement

Visual inspection (800–1200 lux, 20–750px distance)

2D imaging measurement (for complex shapes)

CCD sorting machine (auto-checking dimensions/appearance)

Magnetic flux testing (batch consistency)

6. Reliability Testing

lNeutral Salt Spray (NSS) Test

Temperature: 35±2°C

Salt deposition: 1–2 ml/2000px²·h

pH: 6.5–7.2

Duration: 24h/48h/72h/96h (customizable)

lThermal Demagnetization Test

80°C oven for 2h (customizable duration)

Demagnetization rate ≤10% = Pass

Drop Test Note

Not suitable for impact tests (NdFeB is brittle—may chip/crack).

7. Packaging Process

Defective products removed

Magnetized and neatly arranged

Custom labeling/quantities per box

Vacuum-sealed with anti-magnetic spacers & shockproof padding

Outer box: Moisture/impact/magnetic interference protection

8. Usage Precautions

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

9. Customization & Services

We support:

Dimensions/shape/plating (layers, thickness, color)

Polarity & magnetic strength adjustments

Laser marking (logos/serial numbers)

Special encapsulation & pull-force testing

If you need the samples or Magnet solution, datasheets (MSDS/RoHS), or certifications (ISO9001, IATF16949, etc.), Just contact Jinconn’s sales engineering team, we will reply you in 24 hours.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat