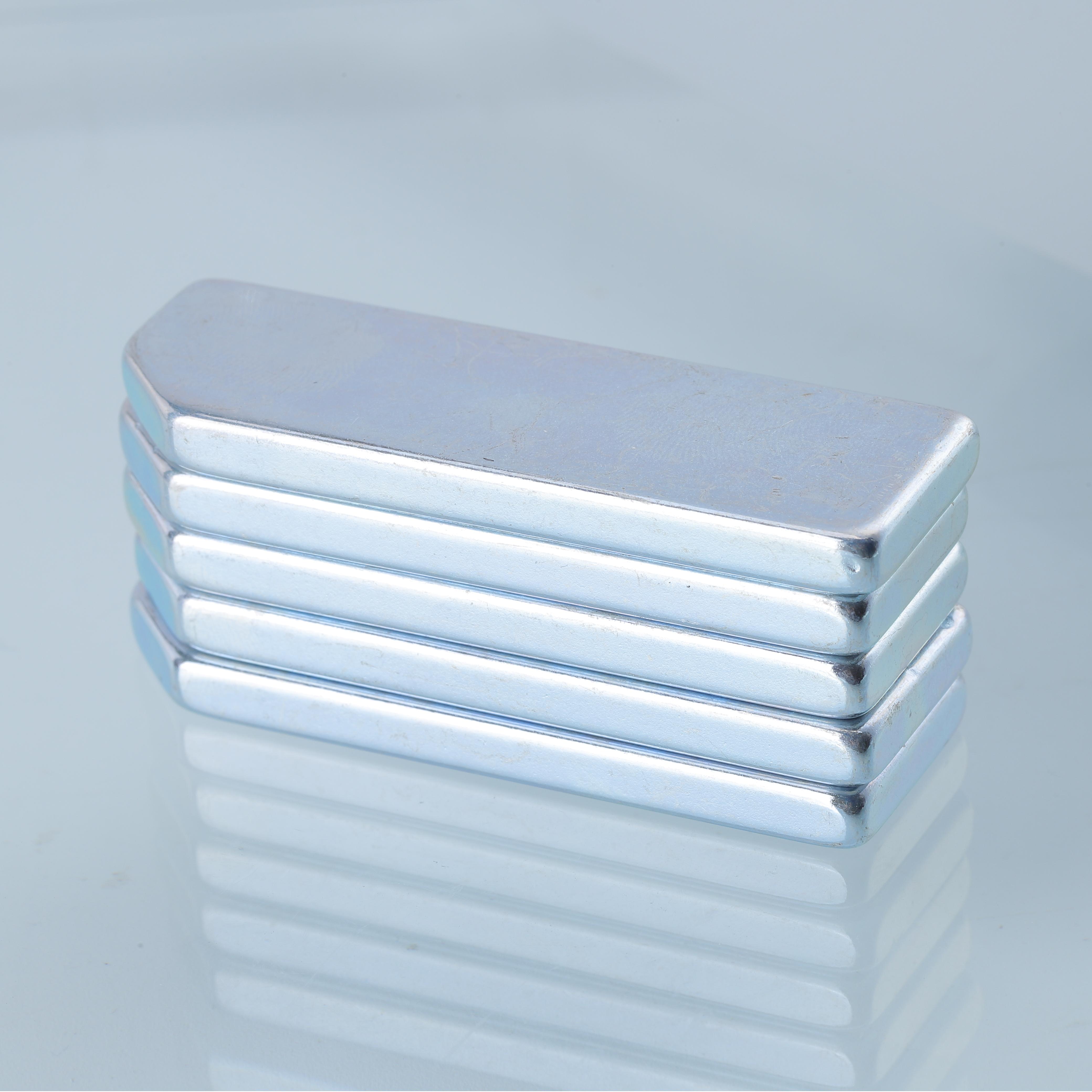

1. Product Overview

The blue and white zinc plated square NdFeB magnet combines high-performance permanent magnetic properties with basic corrosion resistance. It is a practical magnetic component that provides stable magnetic output and economical surface protection. The zinc coating offers moisture and rust resistance, with a bright silver-blue finish that is both functional and visually appealing. Widely used in indoor assembly, electronic fixation, and structural clamping in everyday industrial applications.

2. Technical Parameters

- Product Name: Blue and White Zinc Plated Square Magnet

- Magnet Grade: N52 (Max. Br ≥ 14.8 KGs, Max. Hcj ≥ 10.5 KOe)

- Dimensions: L20*7*2

- Tolerance: L±0.05mm W±0.05mm T±0.05mm

- Operating Temperature: ≤ 80°C (custom high-temp versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 3500±200Gauss

- Magnetic Flux: 1.8mWb (measured with fluxmeter)

3.Manufacturing Process

Wirecutting 3 times to make the shape.

4. Surface Treatment & Coating

Default Plating: Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection

- Manual measurement with micrometers/calipers

- Visual inspection under 800–1200 lumens at a distance of 20–30 cm

- 2D optical measurement for non-standard shapes

- Surface magnetic field and magnetic flux testing to ensure batch consistency

6. Reliability Testing

6.1 Neutral Salt Spray (NSS) Test

- Temperature: 35°C ±2°C

- Salt dposition 1-2 ml/2000px². hour

- pH: 6.5–7.2

- Duration: 12h/24h/48h (customized)

6.2 Temperature Demagnetization Test

80°C oven for 2h (customized duration)

Demagnetization rate ≤10% = Pass

- Simulates real-world thermal stability.

6.3 Drop Test Note

⚠ Not suitable for impact tests (NdFeB is brittle—may chip/crack).

7. Packaging Process & Instructions

- Rejection of items with defects in appearance or dimensions

- Magnetization and neat arrangement of qualified products

- Custom quantity boxing and labeling per client request

- Vacuum packaging with anti-magnetic partitions and shock-absorbing pads

- Final packaging with moisture-proof, impact-resistant, and EMI shielding

(Custom packaging available)

8. Application Fields

- Consumer Electronics: Bluetooth earbud cases, magnetic clasps

- Office & Home: Magnetic pen holders, curtain hooks, whiteboard accessories

- Industrial Components: Magnetic positioning for electrical cabinet covers

- Packaging & Display: Magnetic display modules, hooks, temporary structural fixing

9. Usage Precautions

- Avoid impact and dropping; NdFeB is brittle

- Use sliding motion to separate magnets and avoid pinching

- Pay attention to polarity during installation to prevent magnetic interference

- Store in dry, rust-free environments away from acids, bases, and sensitive electronics (e.g., HDDs, IC cards)

10. Customization & Services

- Customizable in size, shape, magnetic orientation, and zinc coating thickness

- Laser marking for logos and batch codes available

- Support for pull-force testing and packaging design

- Certifications available: RoHS, MSDS, ISO9001

11.Why choose Jinconn magnet / what jinconn offers

11.1 Company Introduction

Dongguan Jinkun New Materials Holdings Co., Ltd. focuses on the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of "Technology as the foundation, Quality as the soul," the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, and are highly trusted by customers both domestically and internationally. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, contribute to the development of the global smart industry, and strive to become a benchmark enterprise and strategic partner in the magnetic materials field.‘’

11.2 System Certification

We specialize in magnetic material solutions, serving a wide range of industries including new energy vehicles, intelligent manufacturing, and electronic communications. With advanced technology and reliable quality, we’ve earned the trust of customers worldwide.

Additionally, we offer free customized magnet solutions—feel free to contact us for more details!

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

-

-

-

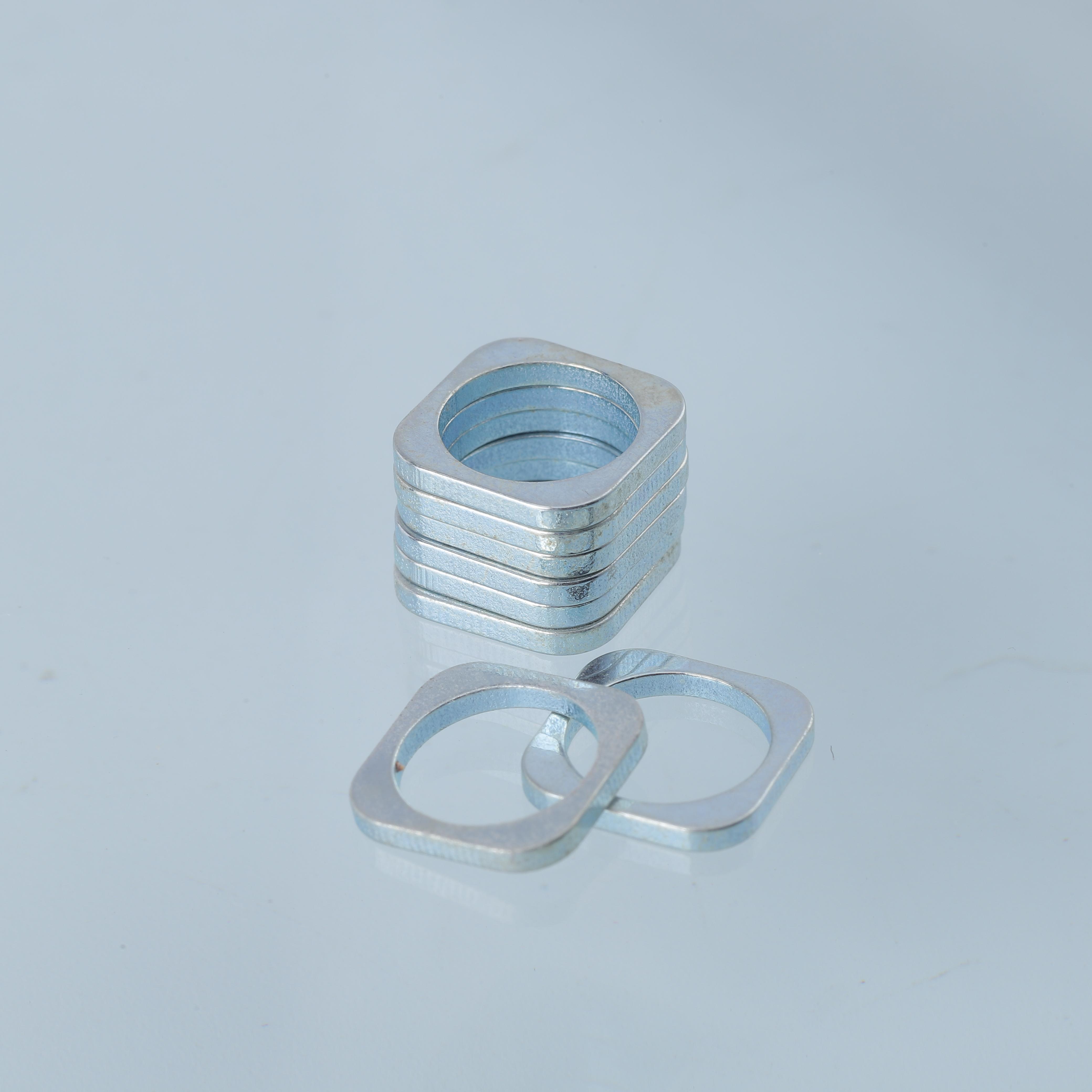

Square High-Performance NdFeB Magnet

Product Name: Square High-Performance NdFeB Magnet

Material Grade: N35 (Remanence Br ≥12.3 kGs, Intrinsic Coercivity Hcj ≥10.8 kOe)

Dimensions: L10×5×3mm (custom sizes available)

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Operating Temperature: ≤80℃ (high-temperature versions customizable)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2500±200 Gauss (measured with Japan TM-801 Gauss meter)

Magnetic Flux Value: 2.0 mWb (measured with flux meter)¥0.00¥0.00

Jinconn WeChat