1. Product Overview

Formed through precision sintering or cutting with specialized molds, L-shaped magnets are designed with specific curved geometries to perfectly fit customized spatial structures. Their superior spatial adaptability and precise magnetic circuit control make them highly capable in complex working environments. Additionally, their structural compatibility enables cross-industry applicability, meeting the personalized demands of customers from various sectors.

2. Technical Parameters

- Product Name: L-Shaped Magnet

- Magnet Grade: 42M (Br ≥ 13.5 KGs, Hcj ≥ 12 KOe)

- Dimensions: Y12 × 7 × 3 mm

- Tolerances: ±0.05 mm in length, width, and thickness

- Working Temperature: ≤ 100°C (custom high-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 3200 ± 200 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 1.8 mWb (measured with fluxmeter)

3. Manufacturing Process

Special-Shaped Cutting: Custom wire-cutting equipment for non-square/non-circular geometries.

Grinding Wheel Molding: Ensures complex structures and high-precision shaping.

4. Surface Treatment & Coating Technology

To enhance corrosion resistance and appearance:Default Plating: Triple-layer Ni-Cu-Ni (customizable).Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection Standards

- Manual dimensional inspection using micrometers/calipers

- Visual inspection under 800–1200 lumen lighting (inspection distance 20–30 cm)

- 2D optical measurement for irregular or non-standard shapes

6. Reliability Testing

6.1 Magnetic Performance Testing:

- Magnetic Field Strength Test: Measures field strength at multiple points to ensure compliance with specifications.

- Magnetic Stability Test: Assesses changes in magnetic properties after prolonged exposure to various temperature and humidity conditions.

6.2 Physical Performance Testing:

- Hardness Test: Uses Rockwell or Vickers hardness testers to ensure wear resistance.

- Density Test: Evaluates structural uniformity and compaction via density measurement.

- Dimensional Accuracy Measurement: Ensures tolerances using calipers and micrometers.

7. Packaging Process & Instructions

- Defective products screened based on appearance and dimensions

- Qualified magnets magnetized and arranged neatly

- Packed in boxes by quantity per customer request with custom labels

- Vacuum packaging with anti-magnetic shields and shock-absorbing pads

- Small boxes placed in outer cartons with moisture, impact, and EMI protection

(Custom packaging available)

8. Application Fields

- High Power Density Motor Systems: Axial flux motors, linear motor magnetic tracks

- Particle Accelerators & Research Equipment: Synchrotron insertion devices, high-field experimental magnets

- Medical Imaging & Therapy: MRI superconducting magnet shielding, proton therapy beam control

- Quantum Technology Infrastructure: Ion trap quantum computers, superconducting quantum chips.

9. Usage Precautions

- Handling: NdFeB material is hard but brittle; avoid dropping or impact

- Safety: Do not bend; slide magnets apart to avoid pinching due to strong magnetic force

- Installation: Follow polarity orientation to ensure normal device operation

- Storage: Keep away from high temperature, humidity, and corrosive environments

- Isolation: Maintain distance from HDDs, IC cards, pacemakers, and other sensitive equipment

10. Customization & Services

- Supports custom dimensions, shapes, coating layers (thickness, color, number)

- Custom magnetic orientation and magnetic strength

- Laser engraving of logos or serial numbers available

- Special packaging solutions and pull-force testing available for specific applications

11. Why choose Jinconn magnet

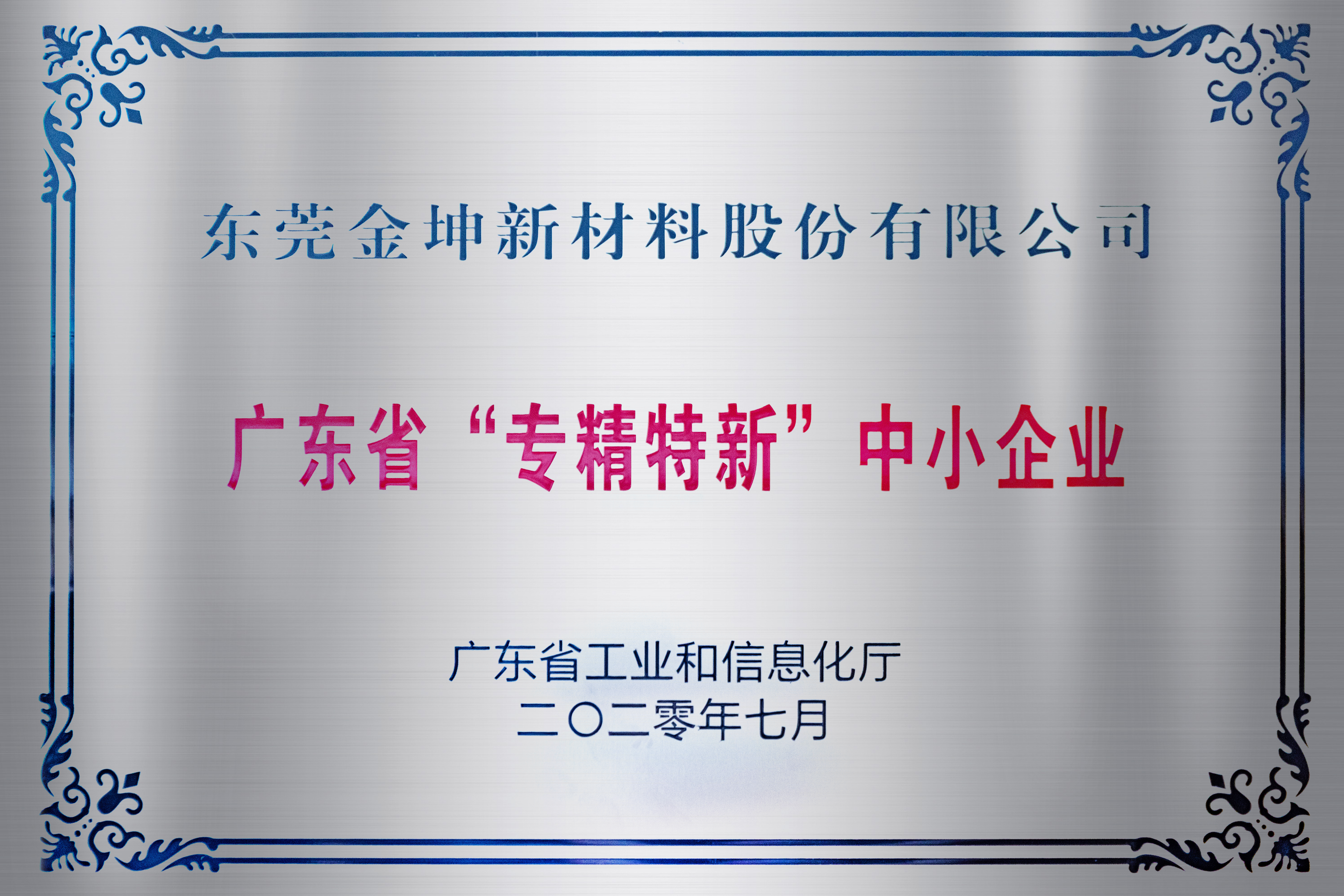

11.1 Company Introduction

Dongguan Jinconn New Materials Holdings Co., Ltd. specializes in the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of “Technology as the foundation, quality as the soul,” the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, support the development of the global intelligent industry, and strive to become a benchmark enterprise and trusted strategic partner in the magnetic materials industry

11.2 Patent

We are dedicated to providing high-performance magnetic material solutions for industries such as new energy vehicles, intelligent manufacturing, and electronic communications. Backed by advanced technology and rigorous quality standards, we are a trusted partner to leading companies worldwide.

We are pleased to offer free customized magnet solutions tailored to your specific needs.

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat

清晰版.png)