1. Product Overview

This tile-shaped NdFeB magnet is made of high-performance sintered neodymium-iron-boron material. It is specially designed for arc-shaped assembly structures and widely used in magnetic assemblies of devices such as brushless DC motors (BLDC), wind turbine rotors, and high-torque industrial motors. The magnet features an arc structure and can be customized in terms of curvature, thickness, inner/outer diameter, and magnetization direction. With optimized arc geometry and precision orientation magnetization, it provides stable and uniform magnetic flux output, ensuring excellent performance even under high-speed rotation or heavy-load conditions.

2. Technical Parameters

- Product Name: Tile Magnet

- Magnet Grade: N48 (Br ≥ 14.3 KGs, Hcj ≥ 10.8KOe)

- Dimensions: Y12 × 7 × 3 mm

- Tolerances: ±0.05 mm in length, width, and thickness

- Working Temperature: ≤ 80°C (custom high-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 3200 ± 200 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 1.8 mWb (measured with fluxmeter)

3. Manufacturing Process

Special-Shaped Cutting: Performed using dedicated non-standard wire-cutting equipment for non-square/non-circular geometric machining.

Grinding & Shaping: Used for complex structures and high-precision contour finishing to ensure dimensional and geometric tolerances.

4. Surface Treatment & Coating Technologies

Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

5. Appearance & Dimensional Inspection Standards

- Manual Measurement with Micrometer/Caliper: Ensures dimensional accuracy and specification compliance.

- Visual Inspection: Performed under standard lighting to detect surface defects or cracks.

- 2D Image Measurement System: Used to measure non-standard or complex-shaped magnets for accuracy.

- Magnetic Flux Testing: Ensures magnetic consistency in each batch to meet design requirements.

6. Reliability Testing

Physical Performance Tests:

- Hardness Test: Uses Rockwell or Vickers hardness testers to ensure wear resistance.

- Density Test: Measures magnet density to assess structural uniformity and compactness.

- Dimensional Accuracy: Uses calipers and micrometers to ensure tolerance compliance.

- High-Temperature Demagnetization Test: Validates magnetic stability in high-temperature environments for long-term performance.

7. Packaging & Transportation

- Defect Screening: Reject magnets with substandard appearance or dimensions.

- Magnetization & Neat Arrangement: Ensures uniform magnetization and packs according to customer requirements.

- Vacuum Packaging: Protects magnets from moisture and magnetic interference.

- Outer Packaging: Shockproof, moisture-resistant, and anti-magnetic interference cartons ensure safe transportation.

8. Application Fields

- Wind Turbine Generators: Used in rotor assemblies to achieve high magnetic energy density and enhance conversion efficiency; suitable for large-scale direct or semi-direct drive systems.

- Industrial Drive Systems: Suitable for servo motors, synchronous motors, and high-torque drive systems, meeting magnetic demands in high-speed, high-precision environments.

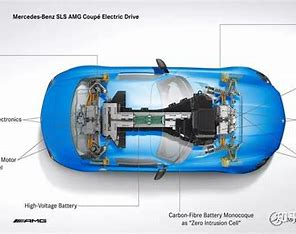

- New Energy Vehicle Systems: Widely used in EV drive motors, electric power steering (EPS) systems to improve response speed and energy efficiency.

9. Usage Precautions

- Handling: NdFeB material is hard but brittle. Avoid dropping, impact, or edge damage.

- Safe Usage: Due to strong magnetism, avoid bending. Recommended to separate by sliding to prevent hand injury.

- Proper Installation: Identify magnetic polarity ends for correct installation to ensure device functionality.

- Storage: Keep away from high temperature, humidity, and corrosive environments. Ensure proper moisture and corrosion protection.

- Isolation: Strong magnetism may interfere with electronics such as hard drives, IC cards, and pacemakers. Maintain safe distance.

10. Customization & Services

- Customizable size, shape, coating (layer count, thickness, color)

- Custom polarity direction and magnetic strength

- Laser marking for LOGO or serial number

- Custom packaging and pull-force testing for specific applications

11. Company Introduction

Dongguan Jinkun New Materials Co., Ltd. focuses on R&D and manufacturing of high-performance magnetic materials. Guided by the principle of "Technology as the foundation, Quality as the soul," it aims to be a global leader in magnetic solutions. Its products are widely used in new energy, smart manufacturing, communications, and healthcare, earning strong trust from clients worldwide.

Request samples, datasheets (MSDS/RoHS), or certifications (ISO9001, IATF16949, etc.) from sales engineers.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat

清晰版.png)