Customized thermal stability black epoxy coated square frame shaped neodymium magnet

1. Product Overview & Application Scenarios

This Customized high adhesive force thermal stability black epoxy coated square frame shaped neodymium magnet with a precision-engineered central hole is designed to deliver exceptional magnetic strength, outstanding corrosion resistance, and superior mechanical durability. Crafted from premium-grade rare earth NdFeB materials, this Customized high speed performance thermal stability black epoxy coated square frame shaped neodymium magnet ensures long-lasting reliability and consistent performance even in demanding industrial environments.

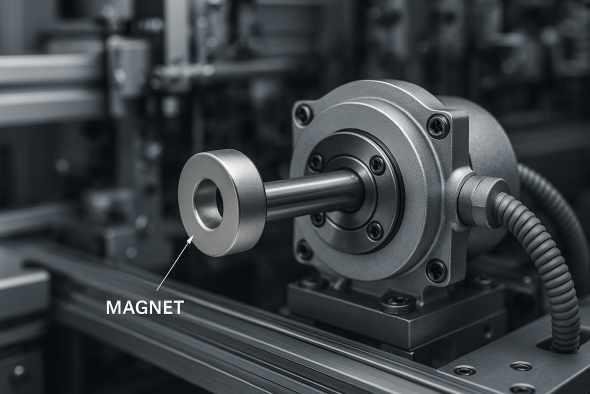

The unique square shape with a central opening allows for seamless integration into motor assemblies, automated machinery, fixture systems, and high-precision alignment mechanisms. Whether used for positioning, clamping, or magnetic coupling, this magnet offers a compact yet powerful solution with a high energy density and low demagnetization risk.

Application examples

Motors & Generators

Integrated into BLDC motors, servo motors, and stepper motors as part of the rotor or stator assembly.

The center hole allows easy mounting onto shafts, gears, or rotary assemblies, improving alignment and assembly efficiency

Automation Systems & Robotics

Used in robotic joints, positioning modules, and linear actuators for magnetic locking or movement control.

Delivers stable holding force for precise and repeatable motion tasks.

Sensors & Instrumentation

Works in tandem with Hall effect sensors, magnetic encoders, and trigger mechanisms.

The central hole allows sensor probes or shafts to pass through, maintaining compact structure and high sensitivity.

2. Technical Specifications

- Product Name: Customized thermal stability black epoxy coated square frame shaped neodymium magnet

- Magnet Grade: N50

- Dimensions: Y40.6x33.3x3.6mm

- Tolerances: ±0.05 mm in length, width, and thickness

- Working Temperature: ≤ 80°C (high-temperature versions customizable)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 4200 Gauss ± 200 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 3.3 mWb (measured with fluxmeter)

3. Surface Treatment & Coating Technology

To enhance this tailor-made thermal stability high adhesive force stable black epoxy coated square frame shaped neodymium magnet’s corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

Laser Surface Alloying:

By using laser cladding of Al-Si powder, a metallurgically bonded surface alloy layer is formed, which can significantly improve the corrosion resistance of the magnet.

Activation Treatment:

Immersion in dilute HCl/H₂SO₄ → Improved coating adhesion

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation

Image Measurement System: High-res cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

Magnetic Flux Consistency Test: Fluxmeters or Hall-effect testers measure magnetic flux across batches to ensure uniform performance in end-user applications.

Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

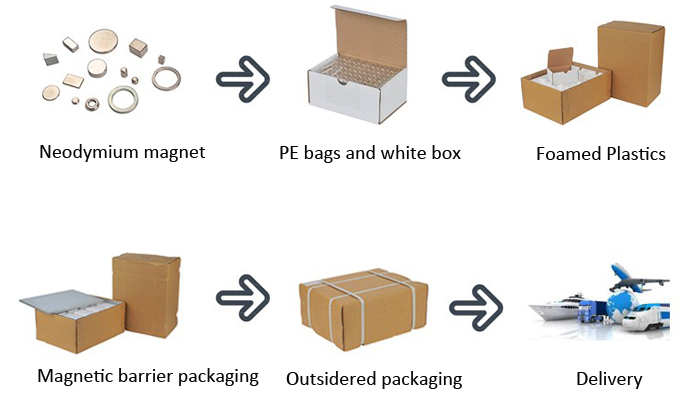

Packaging & Transportation

Quality Control: Every magnet undergoes 100% inspection using calipers, projectors, and automated systems to ensure no defects like cracks, chips, oxidation, or coating issues.

Optimal Magnetization & Packaging: Magnets are evenly magnetized and arranged for efficient packaging and easy automation, tailored to your needs for top performance.

Advanced Packaging: Our multi-layer vacuum packaging, with moisture barriers and desiccants, protects against corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shockproof, moisture-resistant, and anti-magnetic leakage packaging meets international standards, complete with product lists, labels, and tracking codes for easy handling.

At the heart of logistics is more than just movement — it's about delivering on your promises and ensuring customer satisfaction. Our comprehensive solutions provide:

Global logistics coverage to keep you connected everywhere.

Real-time visual tracking for complete transparency at every stage.

Multi-layered security for safe, reliable transport.

Personalized customer service with customized shipping plans tailored to your needs.

With our trusted land, sea, and air network, we help your business reach new heights and expand globally, every step of the way.

FAQ

Q.What kind of surface protection does this magnet use?

A multi-layer coating system is applied:

Outer layer: corrosion-resistant metal coating (e.g., Ni-Cu-Ni or Ni+Sn)

Optional upgrades: Laser surface alloying, Graphene-enhanced composite coating

The coating meets ASTM B633 and IEC 62321 standards for thickness and adhesion

Q. Is the packaging shockproof and moisture-resistant?

Standard packaging includes:

Individual tray liners to prevent magnet collision

Inner cartons with foam or blister protection

Outer boxes with EVA foam dividers for shock absorption

Export packaging compliant with anti-moisture and magnetic shielding requirements

Why Choose us ?

Dongguan Jinconn New Material Holdings Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

· High-Quality Products

We provide high-performance neodymium magnets with strict quality control, ensuring superior strength, reliability, and durability in every product.

· Customization Options

Our magnets are fully customizable, tailored to meet the specific needs of each customer, including unique sizes, shapes, and magnetization directions.

· Advanced Manufacturing Technology

With state-of-the-art equipment and production processes, we maintain consistency and precision, ensuring each batch of magnets meets the highest standards.

· Comprehensive Logistics Support

We offer efficient global logistics solutions, including customized packaging that ensures product safety during storage and shipping, with end-to-end tracking available.

· Strong R&D Capabilities

Our dedicated research and development team constantly innovates, enabling us to offer the latest in magnetic technology and meet evolving industry demands.

Usage Precautions?

Handle with care: Neodymium magnets are brittle—avoid dropping or striking them against hard surfaces.

Separate safely: Always slide magnets apart laterally. Do not attempt to force them apart vertically, as this may cause chipping.

Check polarity before installation: Incorrect orientation may lead to assembly issues or device malfunction.

Protect from corrosion: Store in dry, non-acidic environments. Exposure to moisture or chemicals may degrade performance.

Maintain safe distance from electronics: Keep magnets away from hard drives, credit cards, pacemakers, and other sensitive electronic devices.

Customization & Services

· Customized Magnet Sizes, Shapes, and Coatings: We offer fully tailored magnet dimensions, shapes, and coating options, including multiple layers, varying thicknesses, and color choices.

· Personalized Magnetization & Strength: Magnetization direction and field strength can be adjusted to meet your specific application requirements.

· Laser Engraving: We provide laser engraving services for logos, serial numbers, or other custom markings.

· Specialized Testing: We conduct packaging and suction force testing to ensure performance in unique or demanding applications.

Contact us to receive free samples and customized magnet solutions

Phone/WhatsApp/WeChat: +86 13829120676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

.jpg)

Jinconn WeChat