Heat resistant permanent Thin rare Earth Neodymium square shaped Magnet with round edge

1. Product Overview

The precision customized Heat resistant high coercivity permanent Thin rare Earth Neodymium square shaped Magnets with round edge are engineered with precision and finished with a high-quality plating for optimal corrosion resistance and enhanced durability. These tailor-made high magnetic strength energy efficient Heat resistant permanent Thin rare Earth Neodymium square shaped Magnets with round edge

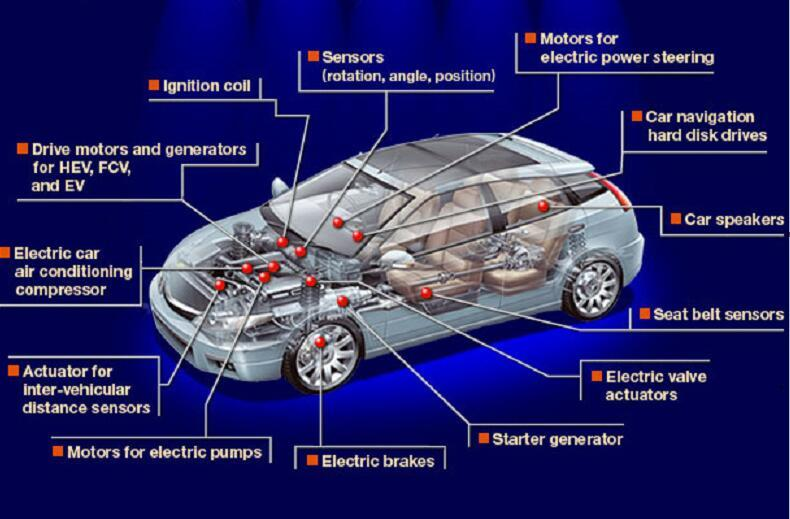

feature a distinctive square shape with rounded corners, making them ideal for applications requiring both strong magnetic performance and aesthetic appearance. Designed for maximum versatility, they are widely used in electronics, sensors, automotive, medical devices, and various industrial applications.

Key Features & Performance

Material: Premium-grade Neodymium-Iron-Boron (NdFeB)

Shape: Square with rounded corners for smooth assembly and safety

Coating: Nickel-Copper-Nickel (NiCuNi) plating for superior corrosion resistance

Magnetization Direction: Through thickness for strong and stable magnetic force

Magnetic Strength: Extremely high magnetic energy product, up to N52 grade available

Size Precision: Tight dimensional tolerances to ensure consistent assembly and application

Advantages

High Magnetic Performance: Provides powerful magnetic force despite its compact size, ensuring reliable operation even in demanding environments.

Excellent Durability: Advanced plating ensures long-term corrosion resistance, making the magnet suitable for humid or harsh conditions.

Safety Design: The rounded corners reduce the risk of chipping, cracking, or personal injury during handling and assembly.

Versatile Applications: Perfect for miniaturized electronic products, precision instruments, sensors, battery packs, switches, medical devices, and custom magnetic assemblies.

Customizable: Various sizes, grades, and coatings are available to meet specific requirements.

2. Technical Specifications

Product Name: Heat resistant permanent Thin rare Earth Neodymium square shaped Magnet with round edge

Magnet Grade: N40 (Br ≥ 13.2 KGs, Hcj ≥ 10.8 KOe)

Product Dimensions: D12-D8*3mm

Tolerance: Outer Diameter ±0.05mm, Inner Diameter ±0.05mm, Thickness ±0.05mm

Working Temperature: ≤ 80°C (customizable for high-temperature versions)

Density: ≥ 7.5g/cm³

Magnetic Field Strength (Surface Gauss): 2900 GS

Magnetic Flux Value: 2.9 mWb (measured with fluxmete

4. Appearance and Dimensional Inspection Standards

To ensure this industrial use thermal stability high remanence thin rare earth small square shaped magnets’ quality consistency and reliability, all products undergo the following strict inspections:

• Visual Inspection under 800–1200 lumen lighting, 20–750px distance

• 2D Optical Measuring System for complex or non-standard structures

• Magnetic Flux Testing to ensure consistency in magnetic performance across batches

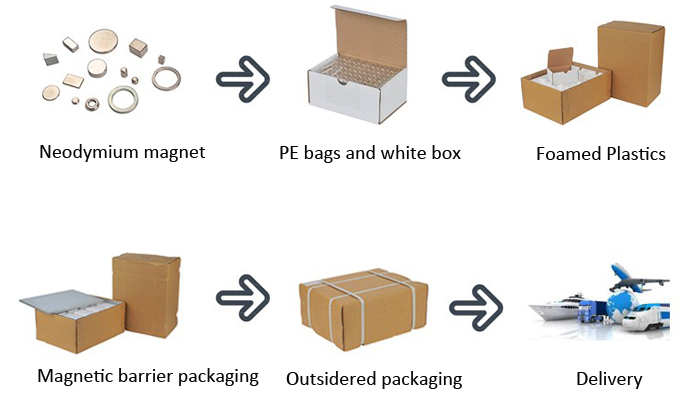

5. Packaging & Transportation

Defect Sorting:

Dimensional and appearance defects are removed before final packaging.

Vacuum Packaging:

Prevents moisture ingress and magnetic interference during shipping.

Outer Packaging:

Shock-resistant, moisture-proof, and anti-magnetic packaging ensures safe transportation.

5. Typical Applications

Industrial Automation:

Fixtures, jigs, robotic arms—ring design allows secure screw fastening for precise positioning.

Tools & Equipment:

Positioning of electric tool components, removable magnetic covers, and instrument panels.

Sensors & Detection Devices:

Magnetic sensors, reed switches, and position detectors.

Medical & Electronic Devices:

Mounting of portable medical equipment and electronic modules—strong magnetic force without interfering with sensitive electronics.

6. Why Choose us ?

Dongguan Jinconn New Materials Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

✅ Rich Industry Experience

With over a decade of expertise in magnetic materials and precision magnet manufacturing, we understand the technical demands of a wide range of industries.

✅ Strong R&D and Customization Capabilities

Our in-house engineering and tooling teams enable us to offer custom-shaped, high-precision, and application-specific magnets tailored to your unique requirements.

✅ Certified Quality Assurance

We adhere to international standards including ISO 9001, ISO 14001, and IATF 16949, with strict quality control from raw materials to finished products.

7. Usage Precautions

NdFeB magnets are hard but brittle; avoid dropping, collision, or edge impacts.

Strong magnetic force may cause pinching—slide magnets apart instead of forcing them.

Ensure correct polarity alignment during installation for stable performance.

Store in dry, cool environments, away from acids, alkalis, or corrosive substances.

Keep away from sensitive equipment such as hard drives, IC cards, and pacemakers.

8. Customization & Services

Custom dimensions, shapes, and coating thickness/color available

Magnetic polarity and force specification as requested

Laser engraving for logos or serial numbers

Special encapsulation and pull-force testing for unique applications

Contact Us:

Phone / WhatsApp / WeChat: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat